Insider News

Latest Issue

Current Issue

Featured Report

Process Intensification: Overcoming the Inefficiencies of Traditional Fed Batch in Upstream Cell Culture

BioProcess Insider Daily - Biotech Week Boston

Read MoreAndrew Mears, CEO of Lead Candidate, highlighted a dichotomy in the industry, where some sectors are downsizing while others are experiencing rapid growth during a video interview at Biotech Week Boston (BWB).

Experts call for better analytics, customization, R&D, and strategic investments as cell and gene therapies struggle with funding challenges and complex manufacturing needs.

Aurigene’s chief commercial officer says his firm and other Indian CDMOs are “a very viable alternative” if major Chinese manufacturers are removed from the US biopharma supply chain.

Cell therapies will play an increasingly important position in AstraZeneca’s broad oncology pipeline, an SVP told delegates at Biotech Week Boston (BWB) last month.

Latest eBooks

See AllSpecial Reports

As the monoclonal-antibody (mAb) market continues to grow, it is becoming increasingly important for pharmaceutical and biotech companies to accelerate process development and establish a scalable manufacturing process capable of achieving high titers and consistent product quality. Central to this is a cell culture media and feed system that can provide the required nutrients for optimal cell growth, viability, and function, as well as facilitate a seamless transition from development to clinical and commercial manufacturing. However, choosing an appropriate system can be a complex and time-consuming process, often requiring the evaluation of multiple medium and feed options. Platform systems, consisting of a medium and complementary feed developed for a specific cell line and application, have emerged as a valuable option for developers to help simplify selection and increase scale-up efficiency. To meet the need for high-performance platform mAb manufacturing solutions, Thermo Fisher Scientific has dev...

Precision in volume delivery is critically important for both the biopharmaceutical and medical device industries. This special report discusses how accurate volume measurement affects patient safety, product quality, and regulatory compliance. Sartorius emphasizes the roles that infusion pumps, laboratory pipettes, and quality control (QC) measures play in ensuring reliable and reproducible results. Register or Login and hit Download Now to get the full Special Report.

Ask the Expert Webcasts

This webcast features: Erin Redman, PhD, principal scientist, & Graziella Piras, PhD , senior director of strategic marketing, life science, 908 Devices. Changes made to the bioprocess can be linked to product quality attributes, but only if there are frequent data points to show the development throughout the bioprocess. Access to good product quality data at frequent timepoints from a full bioprocess can be a tall order for the analytical department. In this webinar, Erin Redman, PhD, principal scientist at 908 Devices, guides us through an easy solution to acquire mAb quality attribute profiling (charge variant profile, sequence identity, and glycosylation profile). Presented here is a simple dilute-and-shoot analysis using ZipChip capillary electrophoresis separation coupled to a high-resolution mass spectrometer. Then, Graziella Piras, PhD, senior director of strategic marketing, life science, describes a case study where a comparison of CHO fed-batch process runs with the usual daily bolus gluc...

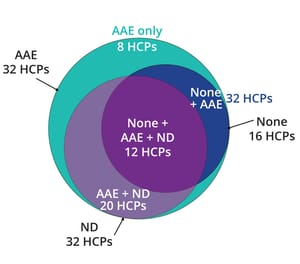

This webcast features: Michael Rauscher, MS, associate principal scientist, process R&D enabling technologies, Merck & Co., Inc. Multimodal chromatography has a history of providing value for biopharmaceutical separations. Ligands that enable binding based on both charge and hydrophobic interactions provide more opportunity for effective separation of multiple product- and process-related impurities. However, more diverse protein therapeutics and evolving expression systems present separation challenges that may not be easily addressed by commercially available multimodal resins. As an alternative to current multimodal anion exchange (MMAEX) resins with quaternary ammonium groups, Bio-Rad’s new Nuvia wPrime 2A Resin offering provides MMAEX functionality with a weak anion exchanger. This webinar will discuss several molecules that were prioritized for high-throughput evaluation of Nuvia wPrime 2A Resin, including an IgG1 monoclonal antibody (mAb), IgG4 mAb, and a bispecific antibody (bsAb), with extra f...