Efficient expression of proteins is an integral part of the biopharmaceutical drug development process. With a range of expression systems, it is important to balance long-term manufacturing goals (e.g., cost of goods and productivity) while matching the expression system to suit the characteristics of a protein (e.g., product quality attributes and long-term stability). Finding the right expression system early on can make or break a therapeutic candidate as it moves from laboratory bench to clinical administration.

Efficient expression of proteins is an integral part of the biopharmaceutical drug development process. With a range of expression systems, it is important to balance long-term manufacturing goals (e.g., cost of goods and productivity) while matching the expression system to suit the characteristics of a protein (e.g., product quality attributes and long-term stability). Finding the right expression system early on can make or break a therapeutic candidate as it moves from laboratory bench to clinical administration.

FUJIFILM Diosynth Biotechnologies has developed its pAVEway™ expression technology to support microbial expression of proteins. This platform technology incorporates three elements in the delivery of an Escherichia coli expression process: optimized expression vectors and control elements, preselected host strains, and platform development using a high-throughput approach for fast strain selection and/or design of experiment (DoE) approaches.

DNA looping in pAVEway™ expression technology is key for controlled, reproducible, and scalable protein expression.

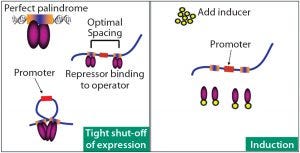

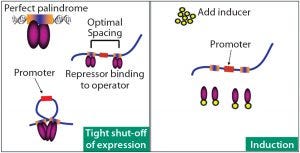

Figure 1: DNA loop formation mechanism that helps control on–off protein expression

DNA Looping and Control Elements

pAVEway™ expression technology is based on unique protein vectors that are designed to maintain transcription control through DNA looping. Looping is generated by specific proteins (repressors) binding to two different sites of DNA, the operator sequences. Once binding happens, intervening DNA base pairs loop out. Low concentration of repressor protein is required to saturate DNA binding sites and form stable loops. DNA looping is critical in generating control of protein expression, and it influences control characteristics. In pAVEway™ expression technology, tight control of basal expression is consistent (Figure 1).

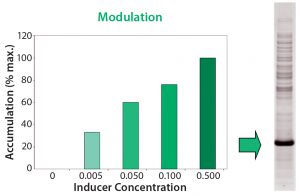

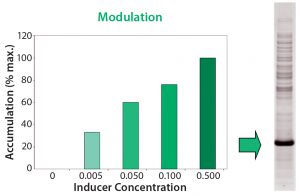

Figure 2: Example of the modulation characteristics and recombinant protein accumulation at different inducer concentrations

No protein accumulation is observed in absence of an inducer. Once inducer Isopropyl β-d-1-thiogalactopyranoside (IPTG) is added, recombinant protein accumulation can be observed. Researchers at FUJIFILM Diosynth Biotechnologies have found that IPTG concentration is proportional to expression rate. The final accumulation level reached is determined by the inducer concentration used (Figure 2). The researchers also have found that when induction happens, the cell population is homogenous and has very consistent expression rates, which is not always the case in other systems.

Having control of protein expression is incredibly powerful. It not only drives higher titers, but it also allows for long-term manufacturing planning because expression can be switched off for multiple generations during a long seed train. Modulation control allows for expression and secretion to be coupled. By allowing slower expression, control can be achieved to maximize protein to be either cytoplasmic soluble or periplasmic secreted, which in turn helps eliminate the ratio of unprocessed forms and rate of insoluble accumulation. With pAVEway™ expression technology, accumulation continues for many hours, with continued cell growth and tuning of expression to match the secretion/folding capacity of a host cell.

Ian Hodgson is head of molecular biology, R&D, FUJIFILM Diosynth Biotechnologies, Belasis Avenue, Billingham, TS23 1LH, UK; 44-1642-364053; [email protected].