Process Supplements for Optimized Fed-Batch Culture Systems

July 1, 2008

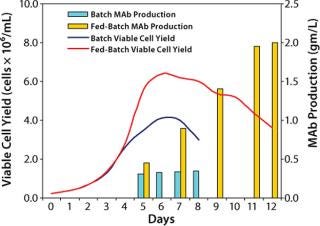

Figure 1.

Fed-batch versions of stirred-tank cell culture have become most popular at large scales. The primary driver of a mid-run addition of nutrients to batch cultures is to increase the quantity of product harvested. The prevalence of fed-batch over other modes is attributable to many practical factors such as reliability, scalability, and application latitude. Increases in the integral of viable cell concentration and volumetric productivity are commonly the greatest improvements obtained (1).

Factors determining optimum feeding of cultures include maintaining desired metabolism in high-density cultures, prolonging cell viability and preventing apoptosis, promoting longevity of cultures, promoting high-quality product accumulation, and encouraging product accumulation.

The six Thermo Scientific HyClone Cell Boost supplements each provide a unique selection of such particular nutrient categories as amino acids, vitamins, lipids, cholesterol, glucose, and/or growth factors in complements for multiple mammalian cell types. All HyClone Cell Boost supplements are chemically defined and contain no animal-derived components. In addition to the HyClone Cell Boost products, other supplement products provide identified nutrients for specific applications, such as concentrated lipids and cholesterol for NS0 cell lines or selected metabolites for cells that use the glutamine synthetase (GS) system.

Today’s experienced fed-batch professionals can expect more than 10 times the efficiencies possible from a few years ago. For some secreted recombinant protein biologicals, yields are now expected to be 1-3 g/L of culture, with 5-10 g/L potentially achievable. As the newest research is applied to production scale, yields exceeding 10 g/L are anticipated (1).

Fed-batch CHO and NS0 formats, particularly in the expression of monoclonal antibodies (MAbs), have demonstrated significant production gains through the application of Cell Boost supplements. Figure 1 shows the result of Cell Boost 2 (Part Number: SH30596) and Cell Boost 5 (Part Number: SH30865) feeding of a suspension CHO cell line cultured in the protein-free medium thermo Scientific HyClone SFM4CHO (Part Number: SH30548). MAb expression levels in this CHO fed-batch culture reached nearly 2 g/L compared with batch cultures peaking at ∼0.4 g/L.

Figure 1. ()

Additionally, fed-batch supplements can be used to overcome process-specific challenges. NS0 cells are known for being cholesterol auxotrophs that require substantial levels of cholesterol to be present in their cell culture medium. The industry move toward disposable cell culture systems using low-density polyethylene (LDPE) culture contact surfaces has created an additional challenge in NS0 (and other cholesterol sensitive cell lines): LDPE film readily adsorbs cholesterol. This competitive uptake of cholesterol between NS0 cells and the LDPE film is fully compensated for by periodic feeding with the animal-component-free cholesterol supplement, Thermo Scientific HyClone LS1000 (Catalog #SH30554).

Advantages of applying process supplements in fed-batch cultures described here represent defined protocols. However, the inherent variability between both individual clones and production platforms often creates a need for specific development and optimization. To support the potential diversity of this work, the six HyClone Cell Boost products are available in powder format, which can by hydrated at a variety of concentrations to support diverse feeding component complements, amounts, and frequencies. The Thermo Scientific HyClone Cell Boost kit (Part Number: SH30890) contains 100-g units of each Cell Boost product to support individual culture demands and responses to various formulations.

REFERENCES

1.) Whitford, W. 2006. Fed-Batch Mammalian Cell Culture in BioProduction. BioProcess Int. 4:30-44.

You May Also Like