Advances in sensor materials and optoelectronics have enabled new optical sensors for use in biotechnology, food and beverage processing, and more. These fiber optic chemical sensors work by trapping an oxygen-sensitive fluorophore or pH indicator dye in a sol-gel host matrix that is applied to an adhesive patch, the tip of a fiber, or a flat substrate such as a cuvette. The indicator materials change optical properties in response to analytes in their environment, and electronics measure the response. For oxygen, the NeoFox Phase fluorometer measures the partial pressure of dissolved or gaseous oxygen. For pH, a spectrometer measures the colorimetric response of the pH dye.

Experimental Conditions

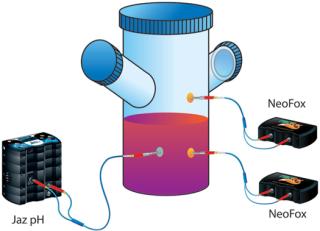

We placed oxygen-and pH-sensitive patches inside a bioflask in which red grape biofermentation occurred. Bioreactors are closed-environment systems in which cells are cultured under specific conditions to synthesize a final product.

RedEye® oxygen patches were attached to the container with adhesive backing to monitor oxygen in headspace and in solution. The pH patches were placed in solution to monitor pH changes during fermentation (Figure 1).

Fresh red table grapes were mashed and left untouched for 48 hours. The juice was drained from the mixture and placed in a bioflask. Yeast cells and nutrients were added to begin fermentation. Nonintrusive oxygen and pH measurements during the aerobic and anerobic processes were monitored over a 60-hour period.

To measure oxygen, we used two NeoFox Phase fluorometers equipped with bifurcated optical fibers for the excitation and detection of the RedEye patches. NeoFox measures the phase shift between a blue LED that excites the oxygen indicator and the emission signal of the fluorescence. The fibers were situated normal to the outside surface of the flask pointing at the patches inside.

To measure pH, we used a Jaz spectrometer with tungsten halogen light source and a bifurcated optical fiber. One leg of the fiber transmitted light to the patch inside the container, and the other leg read the response from the reflective patch inside the solution. Standard pH buffers were used for calibration. Absorbance curves were observed over time.

Results

In the first two hours of fermentation, the RedEye oxygen sensor in the solution detected a quick drop from air saturation as soon as yeast cells and nutrients were added. The yeast cells had started consuming oxygen through the liquid cell membrane by a diffusion process. The pH sensor in the solution measured a slight drop in absorbance as oxygen decreased and CO2 was released.

Headspace remained at air saturation for approximately the first 2.5 hours of fermentation. Once the oxygen in solution was quenched, yeast cells and nutrients started consuming oxygen from the headspace.

Ocean Optics optical oxygen and pH patches can be used within a small-scale biosystem such as a bioflask and provide continuous, nonintrusive monitoring of key system parameters. The ability to monitor DO and pH in real time without perturbing a sealed environment can lead to an improved understanding of the processes in the bioreactor.

About the Author

Author Details

Derek Guenther and Harish Dahbi are sensor R&D engineers at Ocean Optics, Sensors Division, 830 Douglas Avenue, Dunedin, FL 34698; +1-727-733-2447.