Figure 1:

The Mobius CellReady 3-L bioreactor is a single-use, stirred-tank bioreactor ideal for bench-scale cell culture. The CellReady 3-L bioreactor is preassembled and gamma irradiated, significantly reducing turnaround times typically associated with glass bioreactors. There is no need to clean, assemble, or autoclave between experiments. The CellReady 3-L bioreactor ensures maximum operational flexibility with prefitted, weldable tubing and vent filter; two sparging options; and compatibility with most standard bioreactor controller configurations. Designed to replace traditional glass, bench-scale bioreactors, the CellReady 3-L bioreactor has additional functionality through integrated side sampling, addition, and drain ports.

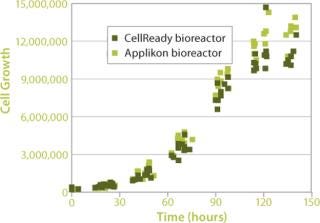

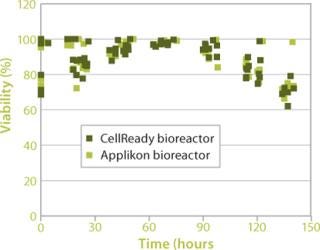

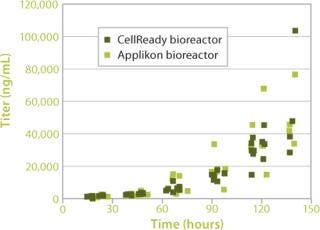

The CellReady 3-L bioreactor was designed to directly replace existing 3-L glass bioreactors, which requires verification of comparable functionality as compared with glass bioreactors. The data shown here demonstrate that with regards to mammalian cell cultivation the CellReady 3-L bioreactor performs comparably to glass bioreactors.

Data Summary

CHO cells exhibit similar growth and protein production performance in both the CellReady 3-L bioreactor and Applikon 3-L glass bioreactors.

Sampling the CellReady 3-L bioreactor had less “dead” volume compared with the traditional glass bioreactor. There was no need to pull a 5-mL sample of void volume prior to sampling, which is necessary with the glass vessel.

Methods

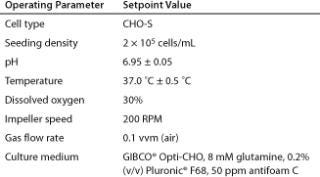

Seven individual bioreactor runs were conducted using Applikon EZ-controls under conditions shown below to evaluate CHO cell growth, viability and titer comparability between the Applikon glass and CellReady 3-L bioreactor vessels.

Cell viabilities were determined by trypan blue exclusion using a Vi-Cell™ counter. IgG levels were determined using an ELISA specific for murine IgG. Cell counts, viabilities, and titers were determined twice daily until the viability dropped below 75% for 2 consecutive sampling points (Figures 123).

Figure 1: ()

Figure 2: ()

Figure 3: ()

Conclusion

The Mobius CellReady 3-L bioreactor shows comparable growth and protein production performance to a traditional glass bioreactor with the benefit of being single-use. In addition, sampling required less volume with the CellReady bioreactor. In conclusion, using the new single-use CellReady 3-L bioreactors for your bench-scale experiments should yield comparable cell culture performance to glass bioreactor vessels while eliminating cleaning, assembly, and autoclaving requirements, allowing you to move onto your next experiment faster.

Millipore and Mobius are registered trademarks of Millipore Corporation. CellReady and the M mark are trademarks of Millipore Corporation. Applikon is a registered trademark of Applikon Incorporated. GIBCO is a registered mark of Life Technologies. Vi-Cell is a trademark of Beckman Coulter. Pluronic is a registered trademark of Sigma-Aldrich. ©2009 Millipore Corporation, Billerica MA, 01821 USA. All rights reserved.

Table 1: Setpoint values for bioreactor operating parameters

Table 1: Setpoint values for bioreactor operating parameters ()