Treefrog Therapeutics has received €10 million ($11 million) over the past five months to support its mass-produced pluripotent stem cell platform C-Stem.

In September, Bordeaux, France-based Treefrog Therapeutics received €450,000 from the French government and €2.4 million from the EU’s Horizon 2020 program to help acelerate the cGMP certification and scale-up of its C-Stem technology platform. It comes five months after the firm raised €7 million in a Series A funding.

“C-Stem is a technology that enables the mass-production of cell therapies,” Treefrog CEO and CTO Kevin Alessandri told this publication. He added the technology has been proven to work, having already been used to deliver a first batch of 143 million Human Induced Pluripotent Stem (IPS) cells to the Imagine Institute in April this year.

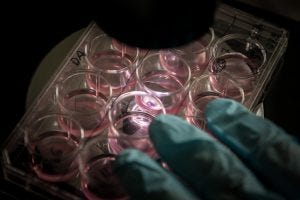

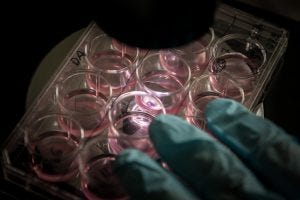

Image: iStock/GerMan101

“Worldwide, $7 billion have been invested last year [2018] in cell therapy research. But the pharma industry does not have a scalable production model delivering affordable and 100% safe cell therapies to serve the market,” he said.

Available cell therapies are produced using 2D methods, which Alessandri said is a labor-intensive process in which a high number of cells die.

Currently, cell therapies available on the market are produced using 2D methods. 2D culture is labor-intensive, long, and a high number of cells die in the process. “As a result, batch size remains limited and production costs are very high.”

And with bioreactor use, approaches have been limited by shear stress, he continued. “Indeed, the mechanical agitation, which is essential for bioreactor culture, does not suit fragile cells such as stem cells. Yields and cell quality remain insufficient.”

Novartis’s Kymriah (tisagenlecleucel), for example, is currently marketed at $475,000 for a single shot.

C-Stem, he said, can overcome these issues and reduce costs by using large batch capacity and conventional bioreactors, along with a high-throughput encapsulation process, and a biomimetic and protective cell culture environment.

“C-Stem is currently the only technology that can meet the worldwide demand for therapeutics cells in terms of volumes, price and quality.”

Treefrog Ambition

With funding in hand, the firm is looking to prepare Good Manufacturing Practice (GMP) certification compliance for C-Stem and use it to scale-up and optimize bioproduction processes. “Today C-Stem enables to cut production costs by 10-fold compared to industry standards,” said Alessandri, adding it has the potential to reduce production costs by 100-fold.

“TreeFrog Therapeutics is currently building a dedicated bioproduction site in Bordeaux, France, to serve its first clients.

“Simultaneously, the company is currently establishing co-development partnerships with cell therapy initiatives and big pharmas worldwide, which could lead to licensing deals. The aim is to develop an integrated, semi-automated device that can be integrated within the production pipeline of cell therapies.”

He summarized: “With C-Stem, TreeFrog Therapeutics can become a world leader in this strategic field and is going to introduce an innovation that will provide access to millions of patients suffering from currently incurable chronic and degenerative diseases with efficient, safe and affordable treatments.”

schedl_b_and_w.jpg?width=100&auto=webp&quality=80&disable=upscale)

schedl_b_and_w.jpg?width=400&auto=webp&quality=80&disable=upscale)