- Sponsored Content

- Chromatography

- Separation/Purification

Ask the Expert: FPLC Column Selection Considerations

March 9, 2021

Sponsored by Astrea Bioseparations

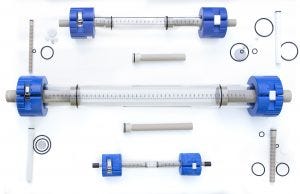

SNAP columns for fast-protein and high-performance liquid chromatographies (FPLC, HPLC), from Astrea Bioseparations

On 10 November 2020, BPI presented an “Ask the Expert” webinar with Dan Yukon (head of North American and global SNAP product sales at Astrea Bioseparations) on considerations for selecting analytical fast-protein liquid chromatography (FPLC) columns. With many options on the market, deciding which type and brand to use can be difficult. To help take out the guesswork, Yukon addressed a number of topics, including pressure and volume considerations; column configuration; materials of construction; frit type, design porosity, and mounting; connection types; adjustability; construction accuracy; packing tube design; and column storage.

Yukon’s Presentation

Speaking from a mechanical engineering background, Yukon explored general considerations for column selection assuming

low-pressure applications

use of glass or plastic columns

manual packing by users.

Volume — of both resin and sample — is the core starting point, Yukon stated. Different resins capture different sample volumes. Once you understand what you’re trying to collect and how much, then you know which resin family to begin with. Suppliers can offer guidance from that point.

Aspect ratio is the ratio of a column’s diameter to its length. For a given volume, you can use a tall, slim column or a short, fat one, the latter allowing for higher flow rates and shorter residence times. Which aspect ratio you need is easy to identify. In size-exclusion applications, for example, samples must have enough time to interact with the chromatography resin. Resin suppliers can suggest the best configuration of their columns for specific applications. Flow distribution also is important. Tall, thin columns generate more wall effects; wide columns with relatively short bed heights need good flow distribution from an inlet connection, typically in a top-center location. You don’t want flow moving only through the center of the bed.

Pressure Considerations: Users should consider carefully the expected backpressure generated by a packed resin bed. FPLC resin beads normally come in sizes of 30–90 µm, making them compatible with most column brands. High-performance resin beads are even smaller (e.g., 20 µm), which can cause significant backpressure in use, creating challenges for glass and plastic columns. Column ruptures from excessive pressure can be dangerous and waste both resin and sample. The larger the resin particle size, the less that backpressure is a concern.

Materials of Construction: Glass is more fragile and brittle than plastic and tends to fail dynamically; plastic typically will crack to relieve pressure. Column materials should be reviewed for compatibility with all slurry, packing, testing, storage, and cleaning buffers and reagents for all wetted components, including seals, frits, flow adapters, and connectors. Yukon also recommended consideration of temperature during these evaluations.

Connections and Frits: Most manufacturers of FPLC systems have standardized their connections to system manifolds to 1/16 inch for small columns or 1/8 inch for larger ones. Tubing to and from a column to a detector should be kept to a minimum to prevent sample diffusion.

Available in a range of materials, porosities, and pore structures, frits often are overlooked and misunderstood. Their function is to facilitate fluid pass-through while holding back chromatography media. Frit porosity should never exceed half the diameter of the resin particle (e.g., ≤20-µm frit pores for a 40-µm resin). But you don’t want to restrict flow through the column. Yukon explained that users should consider the average particle size of their resin as well as the fines content to achieve the best column performance.

Frits can be a potential source of flow hang-up, restriction, and dead volume. Flow rates and backpressure figure into choices made here. Polyethylene is a widely accepted material, but more aggressive solvents can require stainless-steel, sintered-glass, or even titanium frits. Consider frits and O-rings to be consumable/disposable and replaceable components. They should be changed out rather than cleaned every time that a column is repacked.

Testing and Qualification: Successful chromatography operations require a fully tested and qualified column. Asymmetry values and theoretical plates are the standard measurements — often tested with a concentrated injection of NaCl or acetone solution. Yukon said that users must understand the interrelationships among injection volume, overall column/bed volume, and flow rate. The most popular detection method for these evaluations is conductivity.

If a column does not meet your qualification standard, then chromatography results will be compromised or inaccurate. Your resin’s slurry mix needs to be correct, as do the flow rate, compression factor, and evaluation criteria.

Price and Support: Price always is a consideration in selecting FPLC columns. They come in a broad range of configurations, construction materials, pressure ratings, and technical ability — with corresponding price differentials. For academic training and cases for which performance is not an issue, simple gravity-fed columns suffice. They are relatively safe to use and cannot develop dangerous backpressures if misused by inexperienced users. For most bench scientists, however, column cost is relatively insignificant compared with the cost of sample materials. Reliability and reproducible results are important, so hardware should be selected with performance in mind.

A column’s performance is only as good as its packing. Users should consult with resin manufacturers about the best way to pack a given resin. Most media need to be slurry packed, for which proper technique and equipment are required. Users also should consult with column manufacturers.

Scale-Up: During process development, it is incumbent on scientists doing small-scale purification to respect and understand the challenges facing the group that will take the process to the next level. Yukon advised consideration of the “big picture” in anticipation of purification at larger scales.

Developing familiarity with a type of column helps. Doing that enables understanding of challenges involved in packing and configuring those columns. Just selecting a column with a higher initial pressure tolerance than you think you need indicates that the column is built robustly and will be durable in the long run while offering flexibility in the laboratory.

Columns with high pressure tolerance generally can be used at lower pressures. Those with interchangeable components provide further flexibility for future projects. Yukon recommended finding out what maximum size is offered in a given product family.

Yukon added that users must take care in evaluating column suppliers. You need a clear understanding of their stock, lead times, configurations, accessory availability, and so on. Columns with good, repeatable performance and broad availability should be specified in method development to maintain continuity with specifications. When evaluating columns for a particular application, consider not only what you’re going to do today, but also what you and your colleagues might need in the future. Interchangeability is important.

Questions and Answers

What are the most common “rookie mistakes” that you find among scientists who are selecting or using chromatography columns? Particularly in academia and small laboratories, someone is given the task to perform a purification, and they need a column. They grab the first one that looks close to what they need, and they proceed to try to pack it but don’t really understand its parameters and specifications. They assume a diameter and maybe the diametrical tolerance of their column. They may not even change the frits or understand that those left over from a previous experiment are not appropriate for their application. Novices may also spend a lot of time preparing the resin and packing the column, then get a poor result. And that’s when we get a call. The best thing to do is to understand what you have for hardware and what your application requires. Then proceed methodically.

What are some good resources to consider when selecting columns? Suppliers are helpful resources. If you can identify the resin that you would like to pack, then contact the manufacturer and find out if it has any hardware recommendations. Especially if you are buying bulk resin and packing your own column, you want to know whether the supplier can provide application data for you to review before you get started.

Also develop a relationship with your column supplier. It helps to have a three-way dialogue: scientist, column manufacturer, and resin supplier. As a column supplier, Astrea often participates in such conversations. For best possible results on the first or second try, Astrea can make recommendations and head off problems even before the work begins.

You May Also Like