Lonza has partnered with 3D bioprinting materials firm Allevi citing growing biopharma demand for bespoke organs for drug discovery research.

The collaboration – terms of which were not disclosed – will see the Swiss contract development and manufacturing organization (CDMO) combine its primary cells and culture media with Philidelphia-based Allevi’s range of bioprinter and bioink production technologies.

The idea is to cater for biopharma developers looking to manufacture organs and tissues for drug discovery.

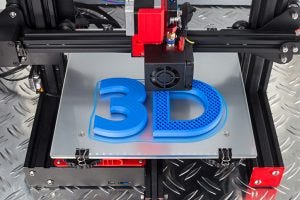

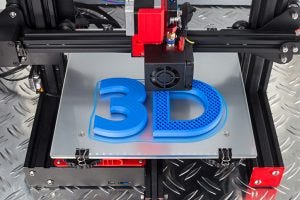

Image: iStock/Grafner

Lonza said it collaborates with selected providers of 3D printing technology to bring the best cell and media tools to 3D bioprinting applications.

It added that “Allevi customers will now have access to Lonza primary cells and media for use in Allevi’s protocols for 3D bioprinting.”

Adding up

3D printing – also known as additive manufacturing �– is the process of depositing material sequentially to form a three dimensional structure.

Usually plastics are used, however, in 3D bioprinting living cells are the building material.

A bioink is a substance made from living cells that mimics an extracellular matrix environment to support the adhesion, proliferation, and differentiation of living cells – effectively the scaffolding of an organ or tissue.

Unlike other biomaterials used as cell scaffolds – including the collagen hydrogel – bioinks can be deposited as filaments during the 3D printing process.

This means the deposition of the bioinks can be precisely controlled, enabling the production of complex structures.

Market

Bioprinting in the biopharmaceutical sector is in its infancy. Much of the focus is on regenerative health rather than the production of organ models for research [1].

That said firms like Organovo, Regenovo, BioDan, Prellis Biologics, and Aspect Biosystems have started developing and selling marketing 3D bioprinted tissues for drug testing and studies [2].

Likewise progress is being made in the bioprinting materials sector.

In August for example iBio entered into a master services agreement with Lung Biotechnology to make a recombinant human collagen based bioink for 3D organs [3].

More recently iBio joined the Advanced Regenerative Manufacturing Institute, a public-private Manufacturing USA initiative focused on the development of next-generation manufacturing processes and technologies for cells, tissues and organs.

References

[1] https://www.sciencedirect.com/science/article/pii/S0167779919300915

[2] https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5935777/

[3] https://www.globenewswire.com/news-release/2019/08/19/1903773/0/en/iBio-Inks-3D-Bioprinting-Agreement.html

[4] https://www.ibioinc.com/news/ibio-joins-manufacturing-usas-tissue-biofabrication-initiative