PALL LIFE SCIENCES (WWW.PALL.COM)

Since 2001, global contract development and manufacturing organization (CDMO) CMC Biologics has completed more than 120 projects with at least 100 pharmaceutical partners. During that time, the company has taken a holistic approach to helping clients balance manufacturing risks and rewards. The team focuses on evaluating key technologies to deploy a constantly evolving set of capabilities in support of biopharmaceutical clients throughout their product lifecycles. Part of that commitment is continually evaluating what would best benefit customers and where key challenges lie.

For monoclonal antibodies (MAbs) specifically, the downstream processing group recognized a need to find alternative processing methods to reduce the cost of protein A capture chromatography. Because of its cost, this step often can be a financial barrier for some pharmaceutical innovators looking to get new drugs to the clinic. When evaluating options, it became clear that continuous, multicolumn single-use chromatography could provide a solution to dramatically lower the cost of this key MAb purification step and facilitate the development of important new medicines.

For monoclonal antibodies (MAbs) specifically, the downstream processing group recognized a need to find alternative processing methods to reduce the cost of protein A capture chromatography. Because of its cost, this step often can be a financial barrier for some pharmaceutical innovators looking to get new drugs to the clinic. When evaluating options, it became clear that continuous, multicolumn single-use chromatography could provide a solution to dramatically lower the cost of this key MAb purification step and facilitate the development of important new medicines.

With the recent introduction of prepacked chromatography columns ranging from a few milliliters to tens of liters in volume, the opportunity for single-use chromatography has become a reality. The option of purchasing prepacked columns from independent suppliers containing chromatography sorbents from multiple vendors has enabled users to convert established chromatography platforms to from self-packed to prepacked. Single-use systems can be configured to operate prepacked columns for a single-use batch chromatography system. The logical extension of these trends is to operate continuous chromatography in continuous mode with multicolumn chromatography systems.

Use of prepacked columns also enables high-throughput screening of different chromatography resins with minimal sample quantities for identification of optimum separation conditions. Flexibility is a further advantage. Limited options for disposable columns is one issue that suppliers are working to address. Some users are hesitant to move from the familiar to the unfamiliar, but that concern is receding as manufacturers continue to expand their use of disposable technologies at large scale.

Why Single-Use and Continuous?

Continuous manufacturing has been used for decades in numerous industries, ranging from automobile manufacturing to petrochemical refinement. Its adoption by the relatively conservative pharmaceutical industry has been slow. However, the US Food and Drug Administration (FDA) is encouraging the sector to consider development of continuous processes because they provide benefits that align well with the agency’s quality-by-design (QbD) and process analytical technology (PAT) initiatives.

Continuous manufacturing requires substantial process understanding and a high level of process automation and control combined with in-line monitoring. Reduced process variability increases process consistency and product quality. Other benefits are related to efficiency and flexibility, with reduced processing times, operating costs, and manufacturing and environmental footprints.

Involving simultaneous use of multiple columns, continuous chromatography is more specifically known as multicolumn countercurrent (MCC) or simulated moving-bed (SMB) chromatography. Steps performed repeatedly during batch chromatography run simultaneously in different small columns (“zones”) during continuous chromatography. With rapid cycling over small columns, the entire chromatography resin lifetime can be used up within a single campaign rather than being split over several campaigns as in multiuse batch approaches.

Product breakthrough is allowed in the load zone of the first column, with the second-pass column capturing that breakthrough. This approach greatly increases the first column’s binding capacity over what is observed in batch processes, reducing the quantities of resin required often by up to 80%. Use of a continuous loading zone improves processing efficiency so that column size can be smaller than that required for batch processes, in which loading pauses each time the column is cycled.

Continuous chromatography is best facilitated with disposable, prepacked columns that can reduce overall costs and improve throughput of chromatographic purifications. This is true even for processes that require expensive sorbents, such as protein A.

Continuous Processing and Protein A Capture

Continuous processing strategies now exist for nearly every process step in MAb production. Indeed, many such strategies can achieve performance similar to corresponding batch-mode configurations. From a CDMO perspective, however, it is important to determine whether a continuous strategy can provide tangible advantages to customers: by reducing costs, improving product quality, increasing productivity, or otherwise.

Protein A capture chromatography is a crucial step in the MAb processing. A highly effective and robust method for removing host-cell proteins (HCPs) and other impurities from harvested cell culture fluid (HCCF), protein A affinity is a platform process step for MAbs that speeds scale-up of downstream processes.

The affinity resin, however, is considered expensive. Costs associated with protein A capture chromatography can be very high. Furthermore, even though the resin typically gets used for only a few cycles in production of material for clinical trials, new resin procurement often is required by regulators for both phase I and phase 2–3 studies. The resin thus gets used to the end of its life only if a product receives market approval and demand for the drug warrants production of several sequential batches with a single packed (multiuse) column.

In fact, the cost of the affinity resin for this important step can influence the decision whether to carry a candidate molecule forward for further development. At larger manufacturing scales, the cost of protein A resin alone can approach the full charge for execution of a manufacturing run at a CMO. Consequently, the high upfront cost of procuring protein A resin can present a barrier for many small to medium innovator companies to getting their new MAbs into clinical testing.

Because continuous chromatography allows for a volume reduction of chromatographic media, switching from batch to continuous mode for this crucial purification step can lessen the cost of the MAb capture step significantly. And that makes single-use column chromatography a more attractive option than it otherwise might be.

Characteristics of Practical Multicolumn Systems

The CMC Biologics downstream process team sought technological solutions to the problems above. Until recently, suppliers offered few solutions for continuous chromatography; the current outlook for this technology is promising. A number of vendors now offer units that operate on the process development scale.

With a sufficient selection available, the team began evaluating different systems and eventually selected three systems to bring into our laboratory for testing. In evaluating the different options, the group was looking for a technological solution that would be fairly straightforward to install and use without the need for extensive operator training. Other criteria included robustness of hardware, functionality of operating software, the level of associated customer support, and the vendor’s readiness to provide a system for good manufacturing practice (GMP) compliance.

The Chosen System

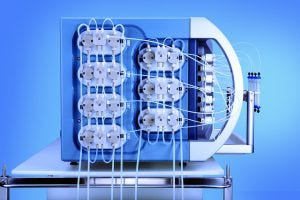

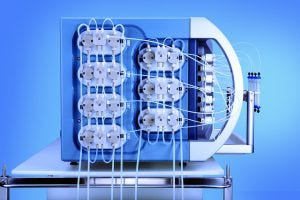

After a detailed evaluation, including physical testing in the plant, CMC Biologics determined that the Cadence BioSMB PD unit from Pall Life Sciences best suited its needs for several reasons, as listed above.

Hardware: The Cadence BioSMB PD unit is unique on the market in that its valve assembly is a disposable unit. The physical equipment for continuous chromatography is complex, with several valves and lengths of tubing. Cleaning such systems can be an involved process. With its disposable valve assembly, Pall eliminates the need for (and costs associated with) cleaning and cleaning process validation — which would be particularly involved in this case. In addition, setup time is shortened and changeover times between products are significantly shortened.

Software: Pall does not require a separate license for software provided with the Cadence BioSMB unit. So users have more flexibility for writing methods for and analyzing results from the system on computers other than the laboratory unit itself. Users also have more freedom to provide input to the vendor for customizing the software interface to meet specific needs.

Customer Support and Collaboration: Pall experts have been accessible and willing to provide assistance to get a Cadence BioSMB PD system set up and running at the CDMO site. Knowledgeable experts — e.g., Marc Bisschops, PhD, who was involved in the development of the technology, and Mark Schofield, PhD, who has tested the unit extensively — have provided insights on how to use the system effectively.

In addition, technical experts at both companies collaborate well (as with other users), and Pall has been open to suggestions from CMC Biologics about how to improve the technology. As mentioned above, the equipment required for continuous chromatography is complex. So direct communication lines and onsite assistance with installation and initial operation of the Cadence BioSMB PD system greatly facilitated the technology evaluation process. Although the system did not fully meet the CDMO’s needs right out of the box, Pall was accessible and accommodating in making necessary modifications to make it more intuitive and robust.

Readiness for GMP: To complement the system, Pall developed its larger-scale Cadence BioSMB Process GMP-compliant chromatography system. For manufacturing use, it is designed to process up to 2,000 L of HCCF within 6–8 hours using up to eight columns. Launched commercially in October 2016, this has been proven to scale up linearly from the Cadence BioSMB PD system. Both design and software systems are compatible to streamline development.

More on the Technology

Both the process development and manufacturing process systems are based on countercurrent technology. Disposable valve assemblies contain all valves necessary to fully automate a range of chromatographic processes, including protein A affinity MAb capture and other types of bind–elute and flow-through chromatography.

The Cadence BioSMB PD system can accommodate up to 16 columns based on the expression titer and desired relative flow rate. The choice is based on the optimum number of columns to process a given process volume (or product mass), so the same BioSMB system hardware can be used even through broad ranges in HCCF titer values. This ability to change the number of columns within the unit for a given chromatographic process provides needed flexibility to match downstream flows.

For CDMOs looking to switch from batch to continuous processing, it is critical to note that the Cadence BioSMB technology was designed to facilitate the switch. In most cases, converted processes use the same chromatographic sorbents, buffer systems, and product-quality assays as the original batch processes.

Of prime concern to a CDMO are the cost savings that can share with its clients. Pall has demonstrated that the Cadence BioSMB PD system can bind at least 40% more protein per liter of chromatography media than a comparable batch process can. In addition, the system’s higher specific productivity provides the same performance using up to 80% less chromatography media as a similar batch process.

Buffer consumption is reduced as well, resulting in fewer consumables required. Additionally, prepacked columns eliminate the need for internal column-packing resources, and cleaning and cleaning validation requirements are decreased by the single-use fluid path. A smaller overall operational footprint allows for smaller tank sizes than would otherwise be necessary, lowers facility utility requirements, and lessens use of water for injection (WFI).

Pall Life Sciences reports significant savings for purification of a 3-g/L MAb feed from a 2,000-L bioreactor. In a typical batch process, a prepacked protein A column (1 × 56 L, 60 cm ID × 20 cm) would be operated in up to four cycles per 8-hour shift (at a 300 cm/h flow rate). But four 4-L (20 cm ID) prepacked protein A columns could be used with a Cadence BioSMB Process system over 11 cycles/batch — or by using five 6-L total (10 cm ID) prepacked protein A columns on the system over 33 cycles/batch.

Work in Progress

Since purchasing the Cadence BioSMB PD system in early 2016, CMC Biologics has been running several different experiments to explore its capabilities for MAb capture. In particular, the downstream process team has slowly increased the number of cycles operated to understand the process space (maximum flow rates, minimum residence times) and robustness of the system for overnight and extended use.

For example, the team first explored the system’s capability for effective purification performance even at short residence times. In batch chromatography, the protein A load phase typically takes 4-to 6-minute residence times to prevent breakthrough of product. It has truly been exciting to observe performance of continuous chromatography processes with residence times of just one to two minutes. Overall, these experiments are designed to confirm that the system can be trusted to function effectively over long periods and that the resin can be cycled many times under the harsher process conditions of high load densities and fast flow rates.

The initial focus for CMC Biologics is on protein A capture for MAbs because of the significant economic benefits that continuous chromatography offers for this particular downstream unit operation. The goal is to demonstrate clearly that for MAbs that perform well in standard batch processes with normal buffer sets, the performance under continuous conditions will be similar. Ultimately the CDMO would like to provide access to this technology for its clients at GMP scale.

Once the technology is well established for protein A capture chromatography, the company will consider switching to continuous operation for other steps. But although multicolumn chromatography can be used for other purifications, the cost benefit is often not as significant because other chromatographic media typically are less expensive than protein A. So although the quantity of resin is again reduced, the increased cost of using several prepacked, disposable columns can have a greater influence on the overall process economics. A CDMO is interested in applying advanced technologies only where they make sense for its clients.

Many process engineers naturally want to link continuous cell culture (perfusion) processes to continuous capture. However, perfusion processes generally provide HCCFs with lower titers over periods of several days — compared with high-titer batch processes of shorter duration. Although perfusion can produce high-quality products, purification of MAbs from such processes can be cumbersome because HCCF must be purified by a protein A capture step during each day of production. Continuous chromatography essentially allows downstream processing to match the cadence of cell culture production by accepting a slow but continuous feed of HCCF over an extended period. So the potential for cost savings from reduced resin costs is not as great in this case, but the opportunity for an elegant solution to improve operational efficiency with continuous chromatography remains. Eluate from the capture step can be frozen and processed in subbatches later, or it could be processed continuously through subsequent steps. Thus, continuous chromatography can act as an enabler for products that require perfusion processing for quality reasons.

Moving forward, the downstream process team at CMC Biologics will evaluate where this technology application will suit both client needs and industry trends. Although the team may consider integrating continuous chromatography with upstream perfusion processes in the future, it currently focuses on the greatest impact the technology can have for clients today in the MAb capture step.

Michelle Najera is a downstream development scientist at CMC Biologics, 22021 20th Avenue SE, Bothell, WA 98021; 1-425-485-1900, fax 1-425-486-0300; [email protected]. Peter Levison, PhD, is senior marketing director for downstream processing at Pall Life Science.