Insider News

Latest Issue

Current Issue

Engineering and Therapeutics

Vaccine Downstream Production: Purification Tools for Various Modalities

Insider Daily: BioProcess International Europe

MoreLab-grown fish offers a sustainable alternative to current seafood production methods but suffers many of the same manufacturing-based pain points as the biopharma industry, says cultivated fish firm BLUU.

Quality and compliance, customer service levels, financials, health and safety, and environmental sustainability are key to multi-modality manufacturing success, Novartis says.

With limited assets, startups must rely on CDMO partners. And working with the right ones is imperative even if it comes with a cost.

.jpg?width=700&auto=webp&quality=80&disable=upscale)

UCB says it built out its internal capabilities to create a process intensified AAV production process based on perfusion after finding limitations when working with external partners.

Latest eBooks

See AllSpecial Reports

Cell viability is the cornerstone of successful outcomes in biotechnology research and therapeutic applications. However, freezing cells, particularly in advanced therapy or vaccine manufacturing, poses significant challenges in maintaining viability after thawing. Freezing rates and specific additives must be understood and controlled so that sensitive cells are not damaged. To identify the optimal freezing rate for maximum cell viability, Single Use Support conducted a comprehensive study using its controlled rate cryogenic freezer to freeze Chinese hamster ovary (CHO-K1) cells. Fill out the form below to read the full report.

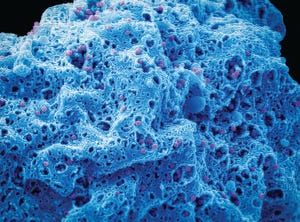

Microbial expression systems are crucial in developing innovative medicines and expanding development pipelines due to the broad range of molecule formats that can be obtained using this technology. However, this approach can be challenging as it requires a variety of manufacturing processes to handle these diverse molecule formats. This is where collaboration with an experienced organization comes into play. Boehringer Ingelheim, known for its proficiency in this technical domain, has a proven track record with 19 commercial microbial products and successful audits and regulatory compliance. The company's commitment to quality and flexibility in implementing production processes make it a reliable partner. Its technology-platform neutrality also simplifies technology and process transfers. Fill out the form below to read the full report.

Ask the Expert Webcasts

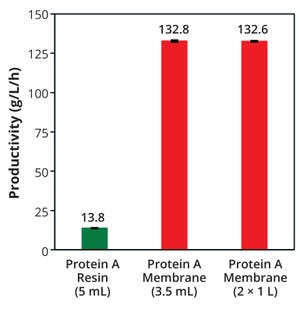

This webcast features: Jan Ott , Research Associate, ZHAW Life Sciences and Facility Management. The current focus in industry and research is on the process intensification of biopharmaceutical production processes. In the upstream process, one promising approach is to switch from fed-batch to perfusion mode, which promises higher productivity. In this collaboration project, an XCell® ATF 6 Single-Use Device operated with the XCell® LS Controller was combined with the Thermo Scientific 50 L HyPerforma™ DynaDrive™ Single-Use Bioreactor. To demonstrate the scalability, the process was also carried out in a 2 L glass bioreactor with an XCell® ATF 2 Single-Use Device. Both cultivations were fully automated regarding bleed, harvest, and glucose control. In summary, the results presented show how highly productive production processes are possible with modern cell retention methods and innovative bioreactors. The scale transfer from laboratory to pilot scale was carried out successfully and comparable results...

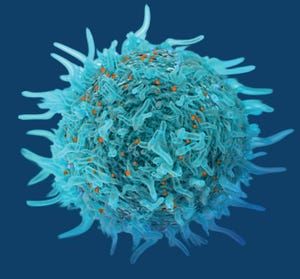

This webcast features: F. Michael Haller, PhD, Principal Scientist , Lonza Biologics & Dan Some, PhD, Senior Principal Scientist , Waters | Wyatt Technology. Downstream purification and enrichment of full capsids for AAV-based gene therapy products, along with aggregate removal, is typically accomplished by ion-exchange chromatography (IEX). Development of this process usually requires sending multiple fractions for offline analysis for each iteration of process conditions, creating a bottleneck that holds back time-to-market and burdens both the development and analytical teams. Real-time multi-angle light scattering (RT-MALS) is a process analytical technique that quantifies biophysical attributes of AAVs including Vg/Cp, titer and aggregation. RT-MALS provides immediate, high-density feedback on critical quality attributes (CQAs) during the chromatography run, eliminating burdensome offline analyses, and enables optimized control over the collection of purified product. This webcast will present RT-...