Microorganism Contamination in Downstream Biopharmaceutical Processes: A Holistic Approach to Measurement, Control, and Prevention

March 7, 2024

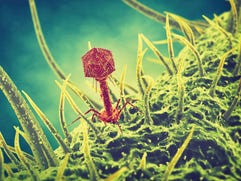

Nonmammalian viruses such as bacteriophages, depicted here, sometimes can serve as substitutes for mammalian viruses during viral-clearance studies.

Biomanufacturing equipment, controls, and testing procedures improve over time in ways that help to reduce the possibility of introducing adventitious viruses into biologic production. Viral contamination of biological products is a real concern. In the 1980s and 1990s, hepatitis and human immunodeficiency virus (HIV) were transmitted to patients through contaminated plasma products (1, 2). Viral removal and inactivation steps had not been implemented for plasma-fractionation, and donor-screening procedures for blood-borne viruses were absent (3). That failure resulted in many deaths and long-term illnesses. One organization that has focused on viral contamination is the Consortium on Adventitious Agent Contamination in Biomanufacturing (CAACB). It has collected comprehensive data on viral contaminations of cell-culture operations from member companies and institutions. The organization has identified 26 contaminations over

36 years of biologics production in mammalian cells (4, 5). To my knowledge, no viruses have ever been transmitted from a contaminated recombinant drug to a patient.

Production-facility shutdowns due to viral contamination incur financial consequences. Those stem in part from the time and resources required for facility decontamination and restart. Other problems can take the form of revenue loss while a facility is nonoperational, ceding of market share to competitors, need for consent decrees and other legal matters, and challenges with regulatory agencies, including fines. In 2010, the US Food and Drug Administration (FDA) fined Genzyme US$175 million for long-standing manufacturing problems related to viral contamination (6).

Process controls are established to limit and even prevent contamination by viruses and other microorganisms. Unfortunately, adventitious-agent testing using good manufacturing practice (GMP)–grade crude harvest often takes several weeks to generate results (7, 8), and harvests typically are processed within 24 hours of collection. Adventitious agents that do not cause pronounced changes in cell-culture outputs are likely to enter downstream processes — and once viruses are downstream of a bioreactor, the decontamination scope expands to the entire facility rather than just the bioreactor and its associated feed and collection lines. Although a robust downstream process is highly likely to remove adventitious agents through multiple orthogonal steps, process controls serve strictly as a safety mechanism. Material that is produced outside of process control must be discarded.

Rapid harvest testing can contain viral contamination to a bioreactor. Thus, a manufacturer receives actionable results before harvest material is clarified and transferred to downstream processing. Rapid testing also ensures that crude-harvest test results can be obtained before harvest expiry. Methods for harvest analysis include high-throughput sequencing (HTS) and quantitative polymerase chain reaction (qPCR) (9, 10). HTS’s advantage over qPCR is that it can detect and measure both known and unknown viruses in a sample. Viral genetic sequences are needed to design adequate probes for viral qPCR testing, so unknown viruses might remain undetected — and thus not be isolated to a bioreactor.

Biologics manufacturers also must place an umbrella of protocols over a process to protect it from adventitious agents such as viruses, fungi, and bacteria (7, 8). Such coverage includes

• careful selection and testing of animal-origin–free raw materials

• adventitious-agent testing of cell banks

• crude-harvest monitoring of cell-culture inputs and outputs

• viral separation and inactivation procedures during downstream processing

• testing of process samples and the process environment for endotoxin, bacteria, and fungi

• facility monitoring and control (air, water, surfaces, material and personnel flows, waste, and room pressurization).

Together, such procedures form a strong barrier to keep viruses out and maintain low levels of bacteria and fungi.

Assessing Viral Clearance in Downstream Processes

Evaluation of downstream-process viral clearance (VC) is an important safety requirement for biological products. The ICH 5A guidance suggests that registrants perform clearance studies using model viruses or viruses that can infect materials of interest. For example, the plasma industry typically assesses clearance of hepatitis C virus (HCV) for human-derived products (11).

VC studies are performed to measure downstream removal of retrovirus-like particles (RVLPs) that can be generated in mammalian-cell processes. Such testing helps to determine an RVLP safety factor, which must be at least 4 log10 greater than the theoretical amount of retrovirus in a dose of product. VC studies also demonstrate the robustness of a downstream process as measured by its ability to remove — or inactivate — multiple types of viruses with different physiochemical properties. Drug developers typically outsource VC studies to specialized testing facilities but sometimes perform them internally.

Guidelines from the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) (7, 8), Parenteral Drug Association (PDA) (12, 13), BioPhorum Operations Group (BPOG) (14), and International Society of Pharmaceutical Engineering (ISPE) (15) all discuss the concept of VC, including its methodology and approaches to interpreting results. Typically, two viruses — minute virus of mice (MVM), a small, nonenveloped parvovirus) and xenotropic murine leukemia virus–related virus (X-MuLV), the enveloped model virus for RVLPs — are used to support early phase clinical studies. Later-phase studies involve VC studies based on at least four viruses, usually two or three in addition to X-MuLV and MVM. Viruses are selected to represent a combination of enveloped, nonenveloped, DNA, and RNA viruses, which are tested on new and end-of-lifetime resins. Other virus selections include reovirus type 3, bovine viral diarrhea virus (BVDV), vesicular stomatitis virus (VSV), Sindbis virus, and pseudorabies virus (PRV), to name just a few possibilities (7, 8).

Below, I explore ways to simplify VC studies, including creation of large VC databases, application of artificial intelligence (AI) to interpret clearance information, and use of bacteriophages and baculoviruses instead of pathogens that infect mammalian cells. I also discuss means for preventing microbial (bacterial, fungal, and viral) incursion into downstream processes.

Simplifying VC Studies Using Virus Substitutes

Drug manufacturers cannot use VC studies to support release of a drug product that was produced from a virally contaminated feedstock. Regardless of the amount of virus present, such material must be discarded. What VC studies provide is assurance that if a process is contaminated unknowingly by the production environment (e.g., from air, water, and operators), then the contaminating viruses are unlikely to be transmitted to patients. Modern biopharmaceutical downstream processes include specific steps for inactivation of enveloped viruses — by low-pH solution (15), solvent and detergent (16), detergent alone (17), or high concentrations of arginine (18) — and virus removal by anion-exchange (AEX) chromatography (19) or viral filtration (20). Although crude cell-culture harvest is tested for adventitious agents (e.g., viruses, mycoplasma, bacteria, and fungi), results often are obtained after production is completed. VC studies ensure that a downstream process can inactivate and/or remove a broad array of viruses with diverse physiochemical characteristics.

VC studies can take several months to complete. A pivotal VC study can cost several hundred-thousand dollars, and in my experience, conducting such a study engages two to three employees for a week or two. Drug manufacturers would welcome any reduction in VC-study complexity, cost, and time that will not compromise patient safety.

Typically, pivotal VC studies involve work with at least four mammalian viruses in specialized laboratories equipped for high biosafety levels (BSLs). Virus panels for both early and late-phase studies include both X-MuLV and MVM. Both are viruses of concern because they infect Chinese hamster ovary (CHO) cells. X-MuLV is a model virus for RVLPs that are endemic in CHO cell lines (usually replication-defective type A and R particles). The remaining study viruses, which are used to demonstrate downstream-process robustness, differ across programs.

Nonmammalian viruses are capable substitutes for both enveloped and nonenveloped mammalian viruses in VC studies. Such pathogens include

• baculovirus, an enveloped virus that replicates only in insect cells (21, 22)

• øX-174, a nonenveloped bacteriophage that infects only Escherichia coli (23)

• ø6 and ø13, enveloped, doubled-stranded RNA bacteriophages that infect Pseudomonas species (24).

Baculovirus (21, 22) and øX-174 (23) can be cultured to high titers — >109 infectious units (IU)/mL and

106–109 plaque-forming units (pfu)/mL, respectively — in a standard laboratory without need for special precautions. Enveloped bacteriophages such as ø6, ø13, and the single-stranded RNA bacteriophage MS2 all can be tested in standard laboratories. But compared with what researchers know about baculovirus and øX-174, less information is available about those enveloped viruses. That includes data about what titers can be obtained in fermentors.

Drug manufacturers also can use virus-like particles (VLPs), which are self-assembling, virus-derived structures that contain one or more viral structural proteins (25–29). Such particles can be enveloped or nonenveloped. They mimic viruses of interest but lack genetic material needed for host-cell infection. VC studies should require significantly less time, money, and labor using such surrogates rather than mammalian viruses.

Nonenveloped Viruses as Surrogates for MVM: MVM and øX-174 are nonenveloped viruses with similar sizes (24.6 nm and 21–29 nm, respectively) (27), isoelectric points (pI, 4.5–6.2 and 6.6) (27, 30), and levels of physiochemical resistance (high). The latter virus does not infect mammalian cells, and it is used to test the integrity of biological-containment suites because its physiochemical resistance equals that of enteroviruses and parvoviruses (31) and exceeds that of adenovirus serotype 5 and poliovirus (32).

Such information suggests that øX-174 might be a reasonable substitute for MVM in some circumstances, although chromatography processes probably would need to be examined case by case. If those two viruses have distinct separation profiles for a given process, then VLPs such as MVM Mock Virus Particle (MVM-MVP) noninfectious surrogates from Cygnus Technologies may be appropriate substitutes (26, 27). In such cases, øX-174 might be useful as a second nonenveloped virus for a full-panel VC study. The comparable size of MVM and øX-174 also suggests that either could be used in clearance assessment for nanofiltration processes (29). Both PP7 and øX-174 phages have served as acceptable substitutes for small mammalian viruses in nanofiltration studies. Lute et al. state that those viruses represented an attractive alternative to MVM because they were easier to manage and study (33). Furthermore, virus removal using 20-nm Viresolve Pro filters (from MilliporeSigma) was similar for samples containing MVM (5.1 to ≥5.9 log10) and øX-174 (5.7 to ≥6.6 log10). Differences in virus removal were due not to filter performance, but to the amount of øX-174 spiked into the process. Bacteriophage PR772 also has been examined as a high-titer surrogate for MVM, one generating high clearance values during nanofiltration (33, 34).

VC studies for nanofiltration processes can be simplified by testing MVM or an MVM surrogate only instead of the standard panel of four or more viruses (35). In nanofiltration, virus removal is size based, depending on a virus particle’s having a larger hydrodynamic radius than that of a membrane pore. Several publications show that parvoviruses (and small bacteriophages) can serve as a worst-case model to assess nanofiltration because they are only slightly larger than standard filter pores (36). Thus, manufacturers would need to report clearance values for MVM, MVM-MVP surrogates, øX-174, or another small bacteriophage.

Nonenveloped Surrogates for VC Chromatography Studies: Scientists can use bacteriophages, VLPs, and noninfectious surrogates to understand the effectiveness of virus removal on novel chromatographic steps. For instance, Chiang et al. used a design of experiments (DoE) approach to assess VC from two monoclonal antibody (mAb) products spiked with two bacteriophages (3). The team used those studies to determine best- and worst-case chromatographic conditions for maximal virus clearance. Furthermore, MVM-MVP technologies and MVM particles have shown comparable performance in AEX, hydrophobic-interaction (HIC), and protein-A affinity chromatography (27). Riordan et al. used øX-174 to show that salt-tolerant membranes can be effective materials for virus removal steps (37).

Enveloped Viruses as Surrogates for X-MuLV: Baculovirus (200–450 nm) and X-MuLV (80–120 nm) show low chemical resistance compared with that of nonenveloped viruses. Baculovirus also is more resistant to low-pH, detergent, and solvent/detergent treatments than is X-MuLV. Baculovirus can survive for one hour at pH 3.0 and

10 minutes at pH 12.0 (38). It also can withstand 90 minutes at 55 °C (38). Baculovirus’s greater physiochemical resistance suggests that it might be appropriate as a second enveloped virus in VC studies. It is similar in size to PRV (150–200 nm), which is often used as a study virus.

The lytic enveloped bacteriophages ø6 and ø13 are similar in shape (icosahedral) and size (~80–85 nm) to X-MuLV (icosahedral, 80–120 nm) (39). Thus, those phages are potential X-MuLV surrogates for nanofiltration processes. The ø6 virions are sensitive to detergents, ether, and chloroform, and they are stable between pH 6.0 and 9.5 (39). However, data are limited regarding their sensitivity to detergents, solvents, and pH conditions used in viral-inactivation processes for protein biologics. Physiochemical comparison is warranted to determine whether ø6 and ø13 can serve as suitable X-MuLV surrogates during evaluation of chromatography and viral-inactivation steps — or whether noninfectious RVLPs would be a better choice. Cygnus Technologies provides kits in which RVLPs have been separated from CHO cells, then purified and concentrated to 108 particles/mL of solution to be used as a spiking agent for downstream assessment (40).

Bacteriophage Production: Bacteriophages are easy to work with and produce high viral titers in standard laboratory fermenters over several hours to several days. For example, Kick et al. propagated bacteriophage M13 in an E. coli–based fed-batch process to yield phage titers of 590 mg/L (41). Such material can be purified by precipitation, ultracentrifugation, and chromatography (typically AEX) (42).

Baculovirus production is also relatively straightforward, but the Spodoptera frugiperda (Sf9) cell line used for propagation can be contaminated with flaviviruses (43). Such contamination must be removed to use the cell line for current good manufacturing practice (CGMP) baculovirus production.

Variability in Low-pH Study Results: Available literature provides many studies of enveloped-virus inactivation in different buffers (44) and at low pH (15, 45–47). For many mAbs, low-pH virus-reduction processes will be comparable and repeatable when set pH, temperature, and product concentrations are maintained. However, in some instances, I have observed inactivation levels 2–4 log10 lower than the mean clearance range for mAbs incubated at pH ≤4.0 — well above the expected variability of ±1 log10 at a given pH, time, and temperature setpoint. Such discrepancies are difficult to understand: Generally, low-pH holds are applied to pooled, low-conductivity material after protein-A affinity purification — although buffer ions and concentrations can have an effect (44). Are the unexpected differences due to genetic drift in the virus stock, contamination of stock with hardier viruses, interaction between virions and target proteins, or an unidentified factor?

Root-cause determination can be an expensive and time-consuming endeavor. One potential approach is to use an X-MuLV surrogate. A manufacturer can challenge the target mAb and a control mAb that previously showed robust X-MuLV clearance with bacteriophages or baculoviruses. If the mAb materials show similar bacteriophage/baculovirus clearance values but result in different X-MuLV values, then problems may be present with the X-MuLV preparation or study execution.

The Role of AI in Establishing Optimal Downstream Processes

Predicting Optimal VC Conditions: The growing maturity of AI raises possibilities for optimizing downstream processes for maximal purity, recovery, and VC (48). Because AI can access and collate considerable amounts of data, it might be capable of accurately predicting VC outcomes based on given process conditions. Prediction accuracy could be checked by comparing AI outputs with other information sources, including experimental data. The comparability of the results would determine whether only the computer algorithms would need to be used or whether a combination of laboratory and in silico data would be required to move forward. The greater the depth of the database used to teach an AI program, the better the output will be — and the lower the amount of independent verification will be needed.

Our industry would benefit from an extensive database of collective VC information to help train AI effectively for process prediction and optimization. Few companies have worked with enough proteins to be capable of training AI to predict chromatographic VC performance, especially considering cases in which the materials and procedures applied are atypical for mAb purification. For example, chromatography processes based on mixed-mode media, ceramic hydroxyapatite (CHT) resins, metal chelation, and hydrophobic interaction are available but nonstandard for mAb purification. Thus, they are difficult to predict, even with sophisticated AI. AEX and protein-A chromatographies, low-pH inactivation, and solvent/detergent treatment processes are more predictable.

Historically, our industry has considered VC data to be proprietary information. Such data can be genericized by removing user-company names and then disclosing a given process’s resin, product-collection buffer and concentration, pH and conductivity levels, column position, and molecule type (e.g., mAb, fusion protein, or other recombinant protein). An extensive database could be managed by a neutral third party such as the PDA or ISPE. Combining a complete database with

in silico models and AI could reduce VC experimentation for regulatory filings. Several companies are actively developing AI for the health and life-science sectors, including Hewlett Packard Enterprise, NVIDIA, and Ginkgo Bioworks. The AlphaFold 2 algorithm developed by scientists at Google DeepMind can predict a protein’s structure and folding behavior based simply on a given amino-acid sequence (49).

Evaluating End-of-Lifetime Resins: In the future, a well-trained AI model could be used to justify not characterizing VC on end-of-lifetime resins. A general industry database could include VC data on unused, intermediate-use, and end-of-lifetime resins from purification processes for many different proteins. Industry-funded experimentation could fill gaps in the database. Eliminating VC studies on end-of-lifetime resin would save substantial time and money. My experience has been that the vast majority of VC values for unused and end-of-lifetime resins applied in a given process fall within ±1 log10 of each other.

End-of-lifetime resin studies also involve demonstration of virus inactivation during column sanitization. Typically, MVM is spiked into a scaled-down column load at a VC facility. Then, a given process is run to completion, the test column is equilibrated, and a “blank” elution cycle is collected and assayed for MVM. The rationale for testing MVM in the blank cycle was that insufficient resin cleaning might leave residual impurities that shield viruses during sanitization. But that hypothesis has not held up (50). In my experience, viruses are rarely detected in blank eluate.

Long-term column performance — as measured by product recovery and purity and by a consistent chromatographic profile — can be maintained with 0.1–1 M NaOH sanitization (50). Such solutions are used extensively in resin sanitization because they effectively inactivate the toughest nonenveloped viruses: the parvoviruses (51). The resin sanitization exposure time exceeds the minimal threshold for MVM inactivation because columns are subjected to several column volumes (CV) of sanitization solution and then held for 60 minutes.

Ultimately, AI could help reduce the work required for studies of column end-of-life, cleaning solutions, and VC more generally. VC studies could be conducted with bacteriophages (øX-174, PR772, ø6, and ø13) or baculoviruses to provide simple, inexpensive solutions.

Controlling Adventitious Agents in Downstream Processing

Although facility control and operation have improved substantially in the past 20 years, process contamination leading to product discard still occurs, resulting in millions of dollars in losses. The risk of viral contamination is extremely low, yet the cost of an occurrence is extremely high, reportedly in the range of US$1–10 million (4). In the worst cases, the cost of investigating a contamination event, implementing corrective actions, decontaminating the facility, and paying for other ancillary costs could be in the hundreds of millions of dollars (5). Can improved downstream processes be designed to limit viral, bacterial, and fungal incursion and growth?

Current downstream processes cannot be closed completely, so they cannot be aseptic. Sterilization can alter chromatography-resin characteristics and performance (52). Furthermore, columns are not sealed devices, and sterilized resins do not remain sterile for long (53). Because we cannot sterilize and close an entire downstream operation, we must operate in closed systems (where possible) and control surrounding environments.

The conditions necessary to inactivate many nonenveloped viruses are more rigorous than those that proteins can withstand. In general, nonenveloped viruses can resist pH extremes, high temperatures, and chemical agents (51). For example, parvoviruses can survive moist conditions at 80–90 °C for 10 minutes and 2,500 ppm of NaOCl. Although NaOCl incompletely inactivates MVM and poliovirus after 10 minutes, the same treatment is effective against adenovirus and vaccinia. Ethanol shows significant efficacy against vaccinia and adenovirus but little activity against poliovirus and parvoviruses (32). Therefore, we probably cannot inactivate nonenveloped viruses by adjusting process conditions. Such viruses must be kept out of downstream processes by controlling facility environments.

Bacterial and fungal product contamination occur more frequently than viral contamination (54). From 2019 to 2021, manufacturers recalled 175 batches containing an identified microorganism and 8–9× that number with an unidentified microbe. Unlike viruses, which cannot multiply in the absence of host cells, bacteria and fungi can ingress into a process stream, multiply, and become difficult to kill. For example, Bacillus species can form spores that resist heat and organic solvents, even under nutrient-depleted conditions (55). Those spores typically are rendered noninfective by moist heat at 110–130 °C for 20–40 minutes. A protein product would be destroyed under such conditions.

Fortunately, many common vegetative bacteria and fungi can be killed under conditions that maintain product integrity. Adding polyols (e.g., glycerol, ethylene glycol, and propylene glycol) to buffers at ≥18% is bactericidal and fungicidal (56). The antimicrobial effectiveness of polyol-containing buffers can be established using concepts outlined in United States Pharmacopeia chapter <51> (57). Developers often consult that monograph for assaying the antimicrobial effectiveness of preservatives. Adjusting pH also can help with microbial control. Many common bacteria thrive in neutral conditions but not in acidic or basic conditions (neutrophiles). A combination of glycol and low or high pH can have a marked effect on limiting microbial growth. And once a polyol-containing buffer is shown to be antimicrobial, buffer lots do not require subsequent testing for bacteria and fungi.

Polyols have a stabilizing effect on proteins and can prevent protein aggregation and denaturation. However, polyols can also affect protein binding to ion-exchange resins (58). Therefore, incorporation of polyols into process solutions for microbial control should be an integral step during downstream process development.

Risk Assessments and Product Disposition

Discovery of a single viral particle leads to product discard, whereas numerical limits are set for bacteria and fungi. A small amount of bioburden is acceptable in starting materials, process intermediates, and bulk drug substances because biomanufacturing operates in a clean but not sterile way. Bacterial and fungal alert and action limits differ by product dose, facility history, product history, process stage, and organism type and amount. For example, enteric bacteria (E. coli and Salmonella species), toxin producers (Staphylococcus aureus), and organisms responsible for allergic responses (Penicillium species) pose higher risks to patients than do typical flora and fauna.

However, all microorganisms produce enzymes and other biological materials. Such molecules cannot be measured during a production process, so they can enter the purification milieu upon cell secretion or cell death. Acceptance of final purified material is based upon a risk assessment of the anticipated amount of expected contaminants and the virulence of the microbe.

BPOG published a white paper examining consequences from bacterial contamination of a manufacturing process with 100 colony-forming units (cfu)/mL of B. cereus (14). That pathogen secretes enterotoxins and is commonly classified as an objectionable organism. BioPhorum studied the theoretical amount of toxin that could be present in a drug substance in the absence of process clearance. The paper includes an interesting claim that even highly toxic contaminants might have tolerable doses.

The authors are probably correct that patient risk from contamination is low, especially because downstream processing should reduce microbial products. However, such studies might fail to account for all bacterial materials that can appear in a drug substance. The 100 cfu/mL of B. cereus used in the BioPhorum study does not account for the total number of cells (living and dead) that are produced during cell culture, the components of which will be released into a process stream. Furthermore, a total toxin amount is difficult to estimate because two B. cereus toxins are secreted into the milieu in amounts that depend on several factors such as cell density, pH, nutrient availability, and oxygen levels. Finally, unknown Bacillus cell components can remain in a drug substance and product, causing allergic or immune responses in patients or perhaps binding the drug of interest.

References

1 Weinberg PD, et al. Legal, Financial, and Public Health Consequences of HIV Contamination of Blood and Blood Products in the 1980s and 1990s. Ann. Intern. Med. 136(4) 2002: 312–319; https://doi.org/10.7326/0003-4819-136-4-200202190-00011.

2 Rosendaal FR, Smit C, Briët E. Hemophilia Treatment in Historical Perspective: A Review of Medical and Social Developments. Ann. Hematol. 62, 1991: 5–15; https://doi.org/10.1007/BF01714977.

3 Chiang M-J, et al. Validation and Optimization of Viral Clearance in a Downstream Continuous Chromatography Setting. Biotechnol. Bioeng. 116(9) 2019: 2292–2302; https://doi.org/10.1002/bit.27023.

4 Anonymous. A United Front. Nature 472, 2011: 389–390; https://doi.org/10.1038/472389b.

5 Barone PW, et al. Viral Contamination in Biologic Manufacture and Implications for Emerging Therapies. Nature Biotechnol. 38, 2020: 563–572; https://doi.org/10.1038/s41587-020-0507-2.

6 Perrone M. FDA Fines Genzyme $175M for Manufacturing Problems. Seattle Times 25 May 2010; https://www.seattletimes.com/business/fda-fines-genzyme-175m-for-manufacturing-problems.

7 ICH Q5A(R2). Viral Safety Evaluation of Biotechnology Products Derived from Cell Lines of Human or Animal Origin. ICH: Amsterdam, the Netherlands, 2023; https://database.ich.org/sites/default/files/ICH_Q5A%28R2%29_Guideline_2023_1101.pdf.

8 ICH Q5A(R1). Viral Safety Evaluation of Biotechnology Products Derived from Cell Lines of Human or Animal Origin. ICH: Amsterdam, the Netherlands, 1999; https://database.ich.org/sites/default/files/Q5A%28R1%29%20Guideline_0.pdf.

9 Charlebois R, et al. Sensitivity and Breadth of Detection of High-Throughput Sequencing for Adventitious Virus Detection. npj Vaccines 5, 2020: 61; https://doi.org/10.1038/s41541-020-0207-4.

10 Lovatt A. Applications of Quantitative PCR in the Biosafety and Genetic Stability Assessment of Biotechnology Products. Rev. Mol. Biotechnol. 82(3) 2002: 279–300; https://doi.org/10.1016/s1389-0352(01)00043-5.

11 Burnouf T. Modern Plasma Fractionation. Transfus. Med. Rev. 21(2) 2007: 101–117; https://doi.org/10.1016/j.tmrv.2006.11.001.

12 TR 47. Preparation of Virus Spikes for Viral Clearance Studies. Parenteral Drug Association: Bethesda, MD, 2010.

13 TR 41. Virus Retentive Filtration (2022 Revision). Parenteral Drug Association: Bethesda, MD, 2022.

14 Bain D, et al. Microbial Monitoring For Biological Drug Substance Manufacturing: An Industry Perspective. PDA J. Pharm. Sci. Technol. 69(3) 2015: 451–460; https://doi.org/10.5731/pdajpst.2015.01070.

15 CMC Biotech Working Group. A–Mab: A Case Study in Bioprocess Development (Version 2.1). International Society of Pharmaceutical Engineering: North Bethesda, MD, 2009; https://ispe.org/publications/guidance-documents/a-mab-case-study-in-bioprocess-development.

16 Farcet J-B, et al. Development of a Triton X-100 Replacement for Effective Virus Inactivation in Biotechnology Processes. Eng. Rep. 1(5) 2019: e12078; https://doi.org/10.1002/eng2.12078.

17 Chen D, et al. Insights into Virus Inactivation By Polysorbate 80 in the Absence of Solvent. Biotechnol. Prog. 36(3) 2020: e2953; https://doi.org/10.1002/btpr.2953.

18 McCue JT, et al. Enveloped Virus Inactivation Using Neutral Arginine Solutions and Applications in Therapeutic Protein Purification Processes. Biotechnol. Prog. 30(1) 2014: 108–112; https://doi.org/10.1002/btpr.1816.

19 Cai K, et al. Virus Removal Robustness of Ion-Exchange Chromatography. Biologicals 58, 2019: 28–34; https://doi.org/10.1016/j.biologicals.2019.01.004.

20 Johnson SA, et al. Virus Filtration: A Review of Current and Future Practices in Bioprocessing. Biotechnol. Bioeng. 119(3) 2022: 743–761; https://doi.org/10.1002/bit.28017.

21 Rohrmann GF. Baculovirus Molecular Biology (4th edition). National Center for Biotechnology Information: Bethesda, MD, 2019; https://www.ncbi.nlm.nih.gov/books/NBK543458.

22 van Oers MM. Opportunities and Challenges for the Baculovirus Expression System. J. Invert. Pathol. 107, 2011: S3–S15; https://doi.org/10.1016/j.jip.2011.05.001.

23 Michel A, et al. Bacteriophage PhiX174’s Ecological Niche and the Flexibility of Its Escherichia coli Lipopolysaccharide Receptor. Appl. Environ. Microbiol. 76(21) 2010: 7310–7313; https://doi.org/10.1128/AEM.02721-09.

24 Daugelavičius R, et al. Penetration of Enveloped Double-Stranded RNA Bacteriophages Phi13 and Phi6 into Pseudomonas syringae Cells. J. Virol. 79(8) 2005: 5017–5021; https://doi.org/10.1128/jvi.79.8.5017-5026.2005.

25 Nooraei S, et al. Virus-Like Particles: Preparation, Immunogenicity, and Their Roles as Nanovaccines and Drug Nanocarriers. J. Nanobiotechnol. 19(1) 2021: 59; https://doi.org/10.1186/s12951-021-00806-7.

26 Cetlin D, et al. Use of a Noninfectious Surrogate To Predict Minute Virus of Mice Removal During Nanofiltration. Biotechnol. Prog. 34(5) 2018: 1213–1220; https://doi.org/10.1002/btpr.2694.

27 Cetlin D. Predicting Viral Clearance in Downstream Process Development. BioProcess Int. 19(5si) 2021; https://bioprocessintl.com/sponsored-content/predicting-viral-clearance-in-downstream-process-development-using-a-noninfectious-viral-surrogate.

28 Johnson S, et al. Characterization of Non-Infectious Virus-Like Particle Surrogates for Viral Clearance Applications. Appl. Biochem. Biotechnol. 183(1) 2017: 318–331; https://doi.org/10.1007/s12010-017-2447-y.

29 Dyer R, et al. Mechanistic Insights into Viral Clearance During the Chromatography Steps in Antibody Processes By Using Virus Surrogates. Biotechnol. Prog. 36(6) 2020: e3057; https://doi.org/10.1002/btpr.3057.

30 Leisi R, et al. Impact of the Isoelectric Point of Model Parvoviruses on Viral Retention in Anion-Exchange Chromatography. Biotechnol. Bioeng. 118(1) 2021: 116–129; https://doi.org/10.1002/bit.27555.

31 Bydzovská O, Mĕrka V. Disinfecting Properties of Performic Acid Against Bacteriophage ΦX174 as a Model of Small Envelope-Free Viruses. J. Hyg. Epidemiol. Microbiol. Immunol. 25(4) 1981: 414–423.

32 Eterpi M, McDonnell G, Thomas V. Disinfection Efficacy Against Parvoviruses Compared with Reference Viruses. J. Hosp. Infect. 73(1) 2009: 64–70; https://doi.org/10.1016/j.jhin.2009.05.016.

33 Lute S, et al. Phage Passage After Extended Processing in Small-Virus-Retentive Filters. Biotechnol. Appl. Biochem. 47, 2010: 141–151; https://doi.org/10.1042/BA20060254.

34 Shukla A, et al. Viral Clearance for Biopharmaceutical Downstream Processes. Pharm. Bioprocess. 3(2) 2015: 127–138.

35 Aranha-Creado H, Brandwein H. Application of Bacteriophages as Surrogates for Mammalian Viruses: A Case for Use in Filter Validation Based on Precedents and Current Practices in Medical and Environmental Virology. PDA J. Pharm. Sci. Technol. 53(2) 1999: 75–82; https://journal.pda.org/content/53/2/75.

36 Gefroh E, et al. Use of MMV as a Single Worst-Case Model Virus in Viral Filter Validation Studies. PDA J. Pharm. Sci. Technol. 68(3) 2014: 297–311; https://doi.org/10.5731/pdajpst.2014.00978.

37 Riordan W, et al. Design of Salt-Tolerant Membrane Adsorbers for Viral Clearance. Biotechnol. Bioeng. 103(5) 2009: 920–929; https://doi.org/10.1002/bit.22314.

38 Chang P-S, Chen L-J, Wang Y-C. The Effect of Ultraviolet Irradiation, Heat, pH, Ozone, Salinity, and Chemical Disinfectants on the Infectivity of White Spot Syndrome Baculovirus. Aquaculture 166(1–2) 1998: 1–17; https://doi.org/10.1016/S0044-8486(97)00238-X.

39 Family: Cystoviridae. Virus Taxonomy: The Classification and Nomenclature of Viruses — The Ninth Report of the ICTV. International Committee on Taxonomy of Viruses: Rockville, MD, 2011; https://ictv.global/report_9th/dsRNA/Cystoviridae.

40 Predicting CHO Retroviral Particle Clearance: MockV RVLP Kit. Cygnus Technologies: Leland, NC, 2022; https://www.cygnustechnologies.com/media/folio3/productattachments/brochures/Cygnus-MockV-RVLP-Report_F_v1.pdf.

41 Kick B, et al. Specific Growth Rate and Multiplicity of Infection Affect High-Cell-Density Fermentation with Bacteriophage M13 for ssDNA Production. Biotechnol. Bioeng. 114(4) 2017: 777–784; https://doi.org/10.1002/bit.26200.

42 Kramberger P, Urbas L, Štrancar A. Downstream Processing and Chromatography Based Analytical Methods for Production of Vaccines, Gene Therapy Vectors, and Bacteriophages. Hum. Vacc. Immunother. 11(4) 2015: 1010–1021; https://doi.org/10.1080/21645515.2015.1009817.

43 Zhang P-F, et al. Susceptibility of the Sf9 Insect Cell Line to Infection with Adventitious Viruses. Biologicals 22(3) 1994: 205–213; https://doi.org/10.1006/biol.1994.1030.

44 Joshi PRH, et al. Advancements in Molecular Design and Bioprocessing of Recombinant Adeno-Associated Virus Gene Delivery Vectors Using the Insect-Cell Baculovirus Expression Platform. Biotechnol. J. 16(4) 2021: 2000021; https://doi.org/10.1002/biot.202000021.

45 Chen Q. Viral Clearance Using Traditional, Well-Understood Unit Operations (Session 1): Low-pH Inactivation. PDA J. Pharm. Sci. Technol. 68(1) 2014: 17–22; https://doi.org/10.5731/pdajpst.2014.00962.

46 Miesegaes G, Lute S, Brorson K. Analysis of Viral Clearance Unit Operations for Monoclonal Antibodies. Biotech. Bioeng. 106(2) 2010: 238–246; https://doi.org/10.1002/bit.22662.

47 Chinniah S, Hinckley P, Connell-Crowley L. Characterization of Operating Parameters for XMuLV Inactivation By Low pH Treatment. Biotechnol. Prog. 32(1) 2016: 89–97; https://doi.org/10.1002/btpr.2183.

48 Buchanan BG. A (Very) Brief History of Artificial Intelligence. AI Magazine 26(4) 2005: 53–60; https://doi.org/10.1609/aimag.v26i4.1848.

49 Eisenstein M. AI-Enhanced Protein Design Makes Proteins That Have Never Existed. Nature Biotechnol. 41, 2023: 303–305; https://doi.org/10.1038/s41587-023-01705-y.

50 Mattila J, et al. Retrospective Evaluation of Cycled Resin in Viral Clearance Studies — A Multiple Company Collaboration. PDA J. Pharm. Sci. Technol. 73(5) 2019: 470–486; https://doi.org/10.5731/pdajpst.2018.009605.

51 Boschetti N, et al. Stability of Minute Virus of Mice Against Temperature and Sodium Hydroxide. Biologicals 31(3) 2003: 181–185; https://doi.org/10.1016/S1045-1056(03)00037-X.

52 Jungbauer A, Lettner HP. Patent EP0762919A1: Sterilization of Liquid Chromatography Resins. European Patent Office: Munich, Germany, 1997; https://patents.google.com/patent/EP0762919A1/en.

53 Klutz S, et al. Developing the Biofacility of the Future Based on Continuous Processing and Single-Use Technology. J. Biotechnol. 213, 2015: 120–130; https://doi.org/10.1016/j.jbiotec.2015.06.388.

54 Biological Product Deviation Reports Annual Summaries. US Food and Drug Administration: Silver Spring, MD, 2023; https://www.fda.gov/vaccines-blood-biologics/report-problem-center-biologics-evaluation-research/biological-product-deviation-reports-annual-summaries.

55 Cho W-I, Chung M-S. Bacillus Spores: A Review of Their Properties and Inactivation Processing Technologies. Food Sci. Biotechnol. 29(11) 2020: 1447–1461; https://doi.org/10.1007/s10068-020-00809-4.

56 Moghayedi M, et al. Neglected Antibacterial Activity of Ethylene Glycol as a Common Solvent. Microb. Pathogen. 107, 2017: 457–461; https://doi.org/10.1016/j.micpath.2017.04.022.

57 USP–NF <51>. Antimicrobial Effectiveness Testing. United States Pharmacopeia: Rockville, MD, 2023; https://doi.org/10.31003/USPNF_M98790_03_01.

58 Handbook: Strategies for Protein Purification. Cytiva: Marlborough, MA, 2021; https://cdn.cytivalifesciences.com/api/public/content/digi-15680-pdf.

Based in Stoughton, MA, Frank Riske, PhD, is a consultant in biopharmaceutical chemistry, manufacturing, and controls at Deep Dive Biotech Consulting LLC; [email protected].

You May Also Like