- Sponsored Content

Ultrasonic Technology: Single-Use High-Precision Flowmeter

August 10, 2016

Sponsored by Levitronix

Levitronix® has released the first ultrasonic, single-use (SU) flowmeter on the market. Characterized by high accuracy and superior performance, LEVIFLOW® SU noninvasive flowmeters enable a highly precise and low-cost flow measurement. With an accuracy of <1% of reading and flow ranges from 1 mL/min to 80 L/min, they offer the highest level of accuracy for measuring liquids in biopharmaceutical and other applications that require FDA, USP-VI, BSE/TSE, and animal-component–free materials that can be gamma sterilized.

Levitronix® has released the first ultrasonic, single-use (SU) flowmeter on the market. Characterized by high accuracy and superior performance, LEVIFLOW® SU noninvasive flowmeters enable a highly precise and low-cost flow measurement. With an accuracy of <1% of reading and flow ranges from 1 mL/min to 80 L/min, they offer the highest level of accuracy for measuring liquids in biopharmaceutical and other applications that require FDA, USP-VI, BSE/TSE, and animal-component–free materials that can be gamma sterilized.

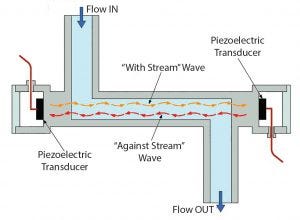

Figure 1: Operating principle of ultrasonic single-use sensor

Technical Background: Figure 1 illustrates the operating principle: Two piezo-electric transducers, mounted in the sensor housing, generate and receive an ultrasonic wave. The wave going in direction of the flow (with-steam wave) is accelerated, and the wave going against the flow direction (against-steam wave) is slowed down. Both waves are processed by a signal converter. The difference of the transit time of both waves is proportional to the velocity of the fluid.

Figure 2: Single-use flow sensor

The standard configuration of Leviflow single-use flowmeters (Figure 2) consists of a flow sensor and a converter with a digital signal processor (DSP) for processing sensor signals. Various signals (analog output, digital input/output) are provided and can be configured with PC software. A two-wire RS485 bus allows arrays of multiple flowmeters. In addition, the sensor value is shown on a four-digit display.

System Benefits

High-precision flow measurement (1% of reading)

Product line covering 1–80 L/min

Gentle to sensitive fluids such as CHO cells and proteins based on ultrasonic technology, no moving parts

High accurate and dynamic flow control with Levitronix® MagLev pump

Highly flexible configuration, same hardware (converter and cables) for SU sensors and clamp-on sensors

Easy integration into OEM equipment

Easy configurable flow sensor parameters

Integrated and configurable totalizer function

Gamma radiation up to 40 kGy

All wet materials of the SU flowmeters made of biocompatible (FDA, USP-VI, BSE/TSE, and animal- component free) polypropylene

Improved bubble robustness due to DSP technology

Applications

High-purity and high-precision liquid processes

Sterilize noninvasive flow measurement in pharmaceutical manufacturing

Biotechnology processing

High accurate and dynamic flow control in combination with Levitronix pump systems

Single-use disposable applications.

Ulrike Flaig is a business development specialist at Levitronix GmbH, Technoparkstrasse 1, 8005 Zürich, Switzerland, 41-44-445-1913; [email protected]; www.levitronix.com.

You May Also Like