- Sponsored Content

- Continuous Bioprocessing

- PAT

Flow Monitoring in Continuous Processing and Single-Use Systems

Sponsored by Sonotec

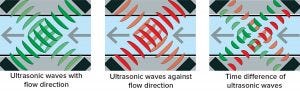

Figure 1: Measuring principle of the SONOFLOW CO.55 clamp-on flow sensors by operating transit-time difference method

Flow sensors placed at critical points in both upstream and downstream processes fulfill the regulatory goals of the process analytical technology (PAT) framework. PAT has been defined as a mechanism for design, analysis, and control of biotechnical and pharmaceutical manufacturing processes through measurement of critical process parameters (CPP). Constant flow monitoring can support its overall targets fundamentally to

reduce production cycling time

prevent rejection of batches

enable real-time release

increase automation and control

improve energy and material use

facilitate continuous processing.

Continuous processing is linked closely to the movement of fluids through a system and involves adjustment of volume and flow rates fed by peristaltic pumps. Noninvasive flow sensors such as SONOFLOW CO.55 sensors can fulfill the requirements of PAT reliably. Within upstream and downstream processes, clamp-on flowmeters have been placed at a number of critical points.

This BPI article explains how noninvasive flow sensors such as SONOFLOW CO.55 sensors can fulfill the requirements of process analytical technology. Just fill out the form below to read it now.

Further Reading

Munk M. A Perfect Pair: Continuous Processing and Single-Use Systems. TechTalk blog: www.nne.com/techtalk/a-perfect-pair-continuous-processing-and-single-use-systems.

CVM/ORA/CDER. A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance. US Food and Drug Administration: Rockville, MD, September 2004; www.fda.gov/downloads/drugs/guidances/ucm070305.pdf.

Melanie Schmidt is director of noninvasive fluid monitoring at Sonotec GmbH. Daniel Thieme is marketing manager at Sonotec GmbH; 49-345- 13317-822; [email protected].

You May Also Like