Developing an End-to-End Scale-Down Model for a Commercial-Scale Downstream Process: Enhancing Technology Transfer Efficiency

Figure 1: Biopharmaceutical manufacturing process overview

Large and complex protein molecules used as therapeutic agents are manufactured in a series of process steps that start with thawing of cell-bank vials and finish with filling and packaging (Figure 1). The cost and complexity of commercial-scale biomanufacturing processes make them prohibitive to troubleshoot or experiment at full commercial scale. Biopharmaceutical companies routinely use scale-down models (SDMs) of licensed commercial-scale processes to evaluate raw material changes, process improvements, and deviations (1) (Figure 2).

Figure 2: Scale-down models reduce time, labor, and costs and enhance ease of use.

Here, we outline some considerations in SDM design, then describe a case study about how an end-to-end representative downstream SDM (E-SDM) was developed and used in a postlicensure process transfer for a biological product.

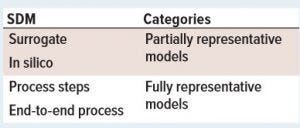

Table 1: Type of scale-down models (SDMs) and categories

Types of SDMs

Many types of SDMs are used to support commercial-scale process activities (Table 1). Surrogate models (e.g., buffer studies) that replace products with surrogates are used to assess and evaluate equipment changes.

In silico models (e.g., mathematical or statistical models) are not yet widely used because of their complexity, but they offer utility in evaluation of process parameters and to enhance process understanding.

Process-step models (e.g., chromatography steps) that represent a single step or multiple commercial-scale process steps are used for impurity clearance studies (e.g., DNA clearance).

E-SDMs are developed to represent the entire commercial-scale process. They have many applications such as evaluation of raw material changes (e.g., media changes), continuous process improvements, process characterization studies, and deviation investigations.

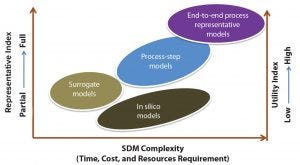

Figure 3: Different types of scale-down models (SDMs) used in commercial-scale processes with respect to their representativeness, complexity, and utility

SDM Categories

SDMs that mimic or simulate the environment that a biomolecule (active pharmaceutical ingredient, API) encounters in a single process step or an entire commercial-scale process can be categorized into fully representative SDMs (Table 1). Typically, process step and end-to-end process models are developed as fully representative SDMs. However, in some cases, if meaningful scale differences exist between an SDM and a commercial-scale process, then process-step SDMs also can be also categorized into partially representative SDMs. Other models such as surrogate and in silico models are inherently partially representative models (Table 1).

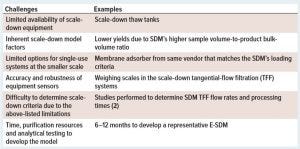

Table 2: Challenges in developing an end-to-end scale-down model (E-SDM)

SDM Representative Index

The extent to which an SDM represents a commercial-scale process can be described on a representative index. Similarly, the extent to which a model can be used to support a commercial scale process can be considered as a utility index. (Note: Both representative and utility indices are qualitative and can vary from process to process.) Figure 3 shows a correlation among the representative index, the time and resources required to develop such models, and their utility index. For cases in which SDM results are ambiguous, then questions focus on the limitations or gaps of the SDM. To maximize the strength of results and decrease questions about SDM validity (high utility index), it is important to design an SDM to be as representative as possible (fully representative).

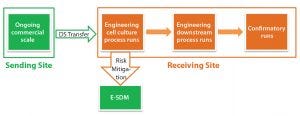

Figure 4: Strategy to enhance drug substance (DS) technology transfer efficiency: Use an end-to-ene scale-down model (E-SDM) to mitigate risk by allowing an early read of cell culture process quality at DS stage

Developing an end-to-end fully representative SDM (E-SDM) is time consuming and includes complexities and challenges as outlined in Table 2.

Case Study: Drug Substance Process Technology Transfer

A technology transfer initiative was undertaken for expanding the manufacturing capacity for a licensed biologic. The need for a representative SDM was identified, as outlined by Kochanowski and Malphettes (3). SDMs can be used to support technology transfer efficiency. Specifically, they can be used to characterize the impact of differences between sending and receiving units in

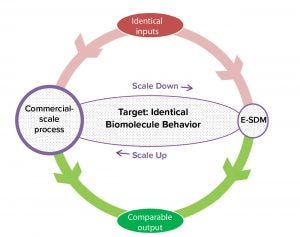

Figure 5: The objective during scaling is to maintain similar or identical biomolecule behavior in both scales.

Raw materials and components

Equipment design

Process changes

Sample handling and storage

Facility changes that lead to differences in product temperature profile, process timing, and so on.

SDMs also are used to

Act as a training platform to familiarize operations staff

Expedite product quality evaluation of materials generated during start up activities (technical, engineering, and confirmatory batches)

Troubleshoot during startup activities (once proven at a receiving site).

Figure 6: The approach used for developing an end-to end scale-down model (E-SDM) with a focus on establishing scale-down criteria for parameters with challenges is to perform feasibility studies to maintain biomolecular behavior as similar or identical to the commercial-scale process.

This case study technology transfer was international and included a new construction of both drug substance (DS) and drug product (DP) facilities. The DS facility was built for upstream cell culture, cell clarification, and downstream purification functionality. The transfer distance and scope of the construction project caused inherent risks to the technology transfer that could lead to differences in the process. Because of construction timing, the DS facility’s downstream area was planned to be completed one year after the upstream area. Development of E-SDM for the downstream process was initiated to ensure an early read of cell culture process quality at DS stage (Figure 4).

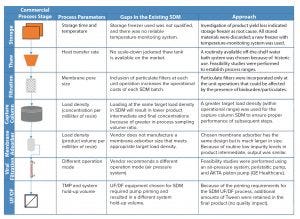

Figure 7: Development of an end-to-end scale-down model (E-SDM); approach used to overcome limitations and challenges (UF/DF = ultrafiltration/diafiltration)

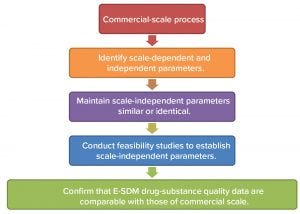

Approach to Developing an E-SDM: The Bayer Manufacturing Sciences and Technology (MSAT) Lab group developed an E-SDM to enhance DS process technology transfer efficiency (Figure 4) by overcoming the challenges listed in Table 2. The objective of the MSAT Lab approach was that the E-SDM should mimic all subtle impacts that the biomolecule encounters throughout the process (Figure 5). To achieve that target, the MSAT Lab took the approach shown in Figure 6. Details of the MSAT Lab approach for developing a single process step (e.g., ultrafiltration and diafiltration (UF/DF) process step) has been published elsewhere (4). Figure 7 summarizes of all process and parameter challenges encountered during development of the E-SDM and the approach used to address them.

Table 3: Quality attributes generated by and end-to-end scale-down model (E-SDM) compared with those at commercial scale for each process step

Comparability of DS Quality Data Generated in the E-SDM: After completing feasibility studies for each E-SDM process step, the MSAT Lab team executed development runs for the entire E-SDM. Results listed in Table 3 confirm that drug substance quality attribute data generated from E-SDM were comparable with drug substance quality-attribute data generated at commercial scale.

An Effective E-SDM

SDMs are not all equal. They are considered either partially or fully representative models. Developing an E-SDM (which simulates the environment a biomolecule encounters throughout the entire commercial scale process) is challenging. We described how one group kept biomolecule behavior similar or identical to commercial-scale processes and thus developed an E-SDM to enhance DS process technology transfer efficiency. Development study results confirm that DS quality attribute data generated by the E-SDM are comparable with those at commercial scale.

Acknowledgments

The authors acknowledge Thuy-Trinh Nguyen, Zach Rogers, and Lawrence Huang for their engagement in discussions on scaled-down parameters and executing downstream scale-down model studies.

References

1 Moscariello J. Scale-Down Models: An Indispensable Tool to Biopharmaceutical Process Development. Am. Pharm. Rev. 30 April 2018.

2 Milne JJ. Scale-Up of Protein Purification: Downstream Processing Issues. Protein Chromatography: Methods in Molecular Biology, Volume 1485. Walls D, Loughran S, Eds. Humana Press, New York, NY, 2017.

3 Kochanowski N, Malphettes L. Technology Transfer and Scale-Down Model Development Strategy for Biotherapeutics Produced in Mammalian Cells. BMC Proceedings. 7(Suppl 6) 2013: 86.

4 Huang L, Rogers Z, Lakshmi PP. Development of a Representative ScaleDown UF/DF Model. BioProcess Int. 16(2)E2 2018.

Corresponding author is Lakshmi Prasad Pathange is a senior manager, Jonathan Tsang is a director, and Venkatesh Srinivasan is a director in the Manufacturing Sciences and Technology Department; Ashley Hesslein is associate director in the Biological Development Department at Bayer US LLC, 800 Dwight Way, Berkeley, CA 94710; [email protected].

You May Also Like