June 2014 Supplement

https://bioprocessintl.com/wp-content/uploads/2014/06/062014Calcott_FDAQuality.mp3

Using contract manufacturing organizations (CMOs) to augment your supply chain is not a new phenomenon in the pharmaceutical industry. One of my first projects in industry involved developing a process for a recombinant protein while manufacturing materials for clinical trials. My team recognized that the company did not have the money to build a plant for manufacturing an unproven product, and it was not bullish to the risk of investing, so we turned to a contract manufacturer in Austria. That was in 1984 — fully three decades ago. Even then, we realized that although the CMO performed the mechanics of making our commercial product, our company still had the responsibility to assure that the work was done right. And we set up systems for necessary oversight.

WWW.PHOTOS.COM

Decades later, I found it surprising when I was working for a small company and confronted by the chief financial officer (CFO). The essence of his argu...

https://bioprocessintl.com/wp-content/uploads/2014/06/062014_LangerOutsourcing.mp3

Budgets for outsourcing activities have rebounded in recent years as outsourcing has gradually become a more common and core strategic decision made by bioprocessing companies. Some of the increase in outsourcing activity over the past few years has no doubt been spurred by cost-cutting behavior. But increasing evidence indicates that contract manufacturing organizations (CMOs) are providing specific technical skills that clients may have shed during leaner recession years. In our latest annual industry report (

1

), we take a close look at outsourcing trends and how they differ regionally.

WWW.FREEIMAGES.COM

We assessed the health of manufacturers’ outsourcing budgets from two angles. First, we included “outsourced biopharmaceutical manufacturing” an area examined in a broad look at budget trends across the industry. Second, we singled out spending on outsourcing of R&D or manufacturing as part of our closer analysis of th...

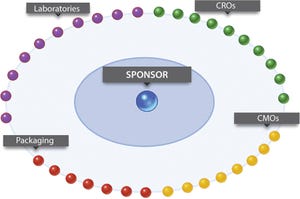

In an increasingly competitive life-science landscape that includes numerous mergers, acquisitions, and changing business models, the demand for collaboration is increasing at such a pace that it exceeds information technology (IT) capabilities. The need to manage and control this collaboration across the supply chain has become mandatory. That is particularly true for larger organizations with hundreds or thousands of partners that are finding new ways to connect, interact, and conduct business. Individual businesses are forming contractual affiliations that extend beyond the physical walls of their companies. Such virtual organizations are made up of many partners and suppliers. Together they make up an intricate web of activities that are necessary to conduct business and to innovate.

This transformation is driven by a number of factors, including the need to reduce costs, take advantage of geographical differences, and adapt to new requirements for the development and supply of biologics. Today’s exte...

https://bioprocessintl.com/wp-content/uploads/2014/06/062014-Galbraith-Biosimilars.mp3

Biosimilars are revolutionizing the bioprocessing industry. Over the years, company CEOs have pushed different models, expanding and closing down huge amounts of internal manufacturing, research and development, and quality control facilities. Sometimes services were pushed to Asia, only to get brought back a few years afterward when a new CEO was appointed. Mergers and acquisitions further complicated those ideas. Consequently, many biopharmaceutical companies now have “gaps” in their drug development service provisions. Filling those gaps will fall on contract research organization (CROs), which now need to pick up the slack.

JUPITER UNLIMITED (WWW.GRAPHICS.COM)

The mainstays of the CRO market have been investigational new drugs (INDs). With IND products, drug developers had over 10 years to design, modify, validate, qualify, change, refinance, fail, redevelop, and finally succeed in licensing their new “blockbusters....

With two products now on the market, and a host of others in clinical trials, antibody-drug conjugates (ADCs) are slowly becoming a big business. Designed to deliver extremely active cytotoxic drugs that are otherwise undosable, they take advantage of the targeting ability of a specifically designed monoclonal antibody (MAb) to “shield” a highly potent API (HPAPI) as it travels through a patient’s bloodstream after administration. Once the antibody reaches its target on the cancer cell, it will release the payload, ready to damage or kill the cancer cell.

The pioneering product in the ADC market was the drug Mylotarg, which was launched by Wyeth (now Pfizer) in 2000 to treat acute myeloid leukemia in elderly patients. It was given accelerated approval by FDA because of a paucity of treatments for the disease. Its antibody component, gemtuzumab, latches on to the CD33 transmembrane receptor, which is expressed on the surface of blast cells, particularly leukemic ones. This is linked to the calicheamicin cy...

https://bioprocessintl.com/wp-content/uploads/2014/06/062014-SidAdvant.mp3

India is becoming an increasingly attractive destination for outsourcing biotechnology services by global biopharmaceutical companies. As “Big Pharma” continues on its path of finding ways to lower costs for development and manufacturing of biopharmaceuticals, Indian contract development and manufacturing organizations (CDMOs) are being viewed as capable and beneficial service providers that possess the necessary technical expertise and regulatory-compliant facilities.

Kemwell Biopharma’s manufacturing and R&D site in Bangalore, India

According to its 11th annual report on biopharmaceutical manufacturing capacity and production, BioPlan Associates ranked India fourth in the world as a potential outsourcing destination (

1

). Survey respondents gave it a “likelihood” or a “strong likelihood” as an option. According to the same report, companies may be seeking CDMOs that are suitable for long-term support of biopharmaceutical develop...

Rapid Development and Scale-Up Through Strategic Partnership: Case Study of an Integrated Approach to Cell-Line and Process Development for Therapeutic AntibodiesRapid Development and Scale-Up Through Strategic Partnership: Case Study of an Integrated Approach to Cell-Line and Process Development for Therapeutic Antibodies

Over the past decade, monoclonal antibodies have become mainstream therapeutics for treating a broad range of conditions from autoimmune disorders to cancer. Part of this evolution is increasing time and cost pressure on biopharmaceutical companies to bring new drugs to market

1

,

2

. Additionally, companies now routinely engineer and screen molecules for developability and manufacturability during discovery before selecting a final candidate molecule. The biosimilar development paradigm also demands significantly more bioanalytical analysis during initial cell-line and process development. Thus, a significant investment is being made to assure that molecules entering the pipeline are successful. It is therefore imperative to take an integrated approach to cell-line development and early stage screening and process development. This enables companies to make appropriate, timely decisions about pursuing therapeutic candidates for preclinical and clinical manufacturing.

WWW.COOKPHARMICA.COM

Cook Pharmica ...

Since the early 1980s, biotechnology products have been a fast-growing sector. They now occupy a significant portion of biologic drugs approved by regulatory authorities around the world every year. Among the approved biologic drug products, as well as those still in clinical testing, many are manufactured by contract manufacturing organizations (CMOs). Sponsor companies often transfer their developed process and process knowledge to CMOs for manufacturing of materials for toxicology and clinical studies.

Figure 1:

Life cycle of drug-product development

Figure 1 illustrates the usual life cycle of drug product development. Typically drug candidates go through various research screening and optimization stages, with one optimal variant selected and moved into preclinical development. During preclinical development, a selected molecule will be further assessed for preliminary safety and potency through a series of in vitro and in vivo testing. Meanwhile, stage-appropriate manufacturing processes and formul...

byYun Bai

BioVectra Inc. is an eastern Canadian contract manufacturing organization (CMO) with expertise in both synthetic chemistry and biomanufacturing techniques. In recent years, it has obtained specialized knowledge in production of highly potent small molecules from fermentation and functionalized methoxypoly(ethylene glycol) products (mPEGs). The focus of BioVectra’s contract manufacturing business is the transfer and scale-up of processes for manufacturing its clients’ products under current good manufacturing practices (CGMPs) as appropriate for the clinical stage of each product.

In the current environment, CMOs play an increasingly important role in management of global manufacturing capacity. Growth of the contract manufacturing industry has been at least partially based on the premise that externalization of manufacturing can lead to more efficient use of global manufacturing capacity. More efficient capacity use lowers costs associated with manufacturing drug products and substances — and ultimately, ...