Microvolume Sample Quantitation for Bioprocessing QC, Manufacturing, and Analytical Labs

July 1, 2009

In industries where implementation of process analytical technology (PAT) is bringing significant benefits and improvements to many processes, any new supporting technology that helps manufacturing efficiency and lowers production cycle time is often adopted in various functional areas throughout the organization. Bioprocessing operations often need to determine nucleic acid or protein concentrations reliably and with fast sample turn-around time at various stages during manufacturing.

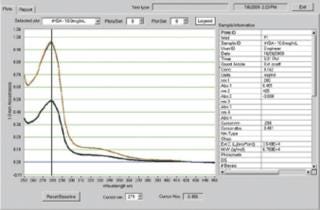

A common practice today is UV-Vis absorbance spectroscopy using conventional cuvette-based spectrophotometers. However, a novel approach using a microvolume UV-Vis analysis method is providing significant improvements in processing time as well as reliability.

The Thermo Scientific NanoDrop™ 8000 UV-Vis spectrophotometer uses a patented sample retention technology that allows direct measurements for samples as small as 1 µL across a broad concentration range without the need for dilutions. Analytical laboratories, manufacturing, and QC operations can benefit greatly from this technology. On the manufacturing floor, it is important to analyze the concentration of the intermediate bioproducts to assess quality and determine potential modifications to downstream manufacturing steps.

With the need to perform dilutions eliminated, thereby minimizing human error and variability factors, analyses can be done quickly and conveniently on the manufacturing floor with the NanoDrop 8000. Analysis can be performed within minutes and with minimal sample waste, significantly reducing total processing time. Because NanoDrop 8000 does not have any associated consumables, operating costs are reduced.

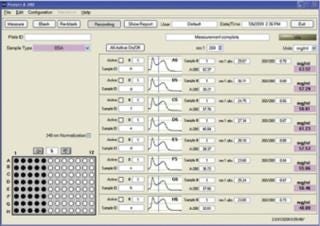

With the ability to measure up to eight samples at a time, and a simple and user-friendly interface that makes it easy to train manufacturing floor operators, the NanoDrop 8000 allows for improved at-line productivity. A small footprint also makes it easily portable to wherever it is next needed on a busy manufacturing floor.

Another significant feature is the ability to develop custom configured methods allowing users to specify testing parameters including the absorbance wavelength of the analyte in question. For bioprocessing operations that may have to handle unique biomolecules or contract facilities that deal with many different customer requests, this added flexibility is a key advantage in the quality control procedure.

NanoDrop Products has a free trial program that allows companies to try an instrument at their facility free of charge. NanoDrop pays all shipping and handling costs. Visit www.nanodrop.com/TrialProgram.aspx for additional details.

You May Also Like