Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

November 2, 2012

Sponsored Content

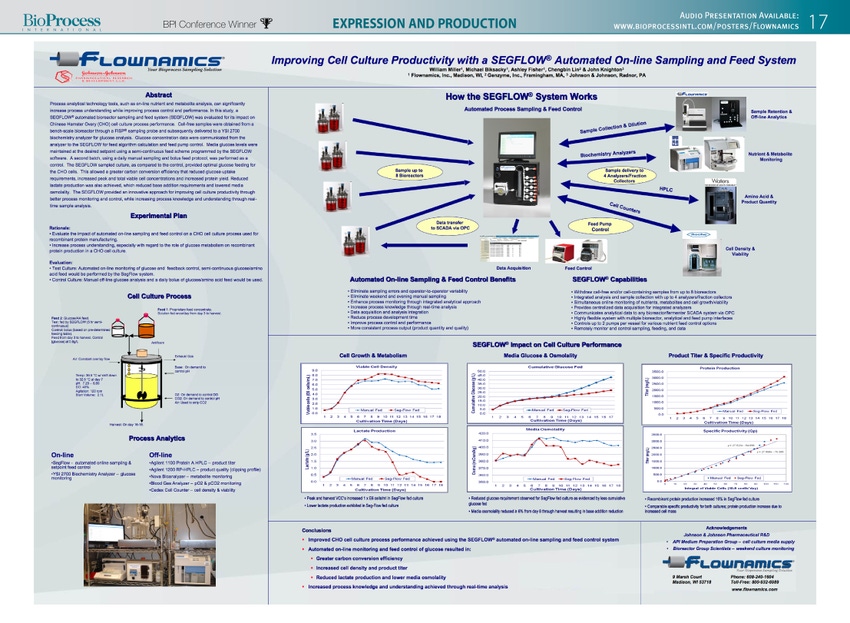

A SEGFLOW® automated on-line sampling and feed system (SEGFLOW) was evaluated for its impact on Chinese Hamster Ovary (CHO) cell culture process performance in bench-scale stirred tank bioreactors. The SEGFLOW was integrated with a YSI® Biochemistry Analyzer and a nutrient feed pump allowing real-time glucose analysis and automated glucose feeding to be performed for the test batch. In contrast, a batch using daily manual sampling and bolus feed protocols, was performed as a control. For the SEGFLOW culture, media glucose levels were maintained at the desired setpoint using a semi-continuous feed scheme programmed by the SEGFLOW software. By automating glucose monitoring and feed control, the SEGFLOW system provided an optimized nutrient environment for the CHO cells, allowing greater carbon conversion efficiency for the culture. As a result, reduced glucose uptake requirements were realized, increased peak and total viable cell concentrations were observed and product yield was increased. Reduced lactate production was also achieved, which lowered base addition requirements and media osmolality. The SEGFLOW provided an innovative approach for improving cell culture productivity through better process monitoring and control, while increasing process knowledge and understanding through real-time sample analysis.

You May Also Like