Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

November 16, 2017

Sponsored by Extract Technology

With numerous cellular and gene therapy products seeing strong initial clinical successes, investment in next-generation technologies by both large bio/pharma companies and start-up specialist firms has been significant.

In fact more than 750 companies worldwide declare themselves to be in the “regenerative medicine” market space, with a high percentage of year on year increases in the number of cellular and gene therapy drugs in clinical trials.

Many of these companies are eager to advance from early stage clinical trials to phase III and commercial products, but lack the manufacturing capability.

There is a significant need for equipment manufacturing partners with the specialised expertise necessary to innovate and implement novel manufacturing solutions that will help accelerate the commercialisation of these advanced treatments with the tremendous potential to improve patient lives.

Typically both cell and gene therapies are produced in fixed facilities that require a significant upfront investment. Modular concepts offer an opportunity to shift from these large, fixed assets to networks of smaller, standardised manufacturing systems where smaller processes require higher segregation and containment.

By using standardised, modular designs for manufacturing isolators, companies have the potential to accelerate drug development and launch; defer decision-making on adding capacity until later in a product lifecycle when there is more certainty about clinical trial success and market projections; and enable the rapid addition of capacity by ‘scaling out’ to respond to changes in market demand without disrupting existing operations.

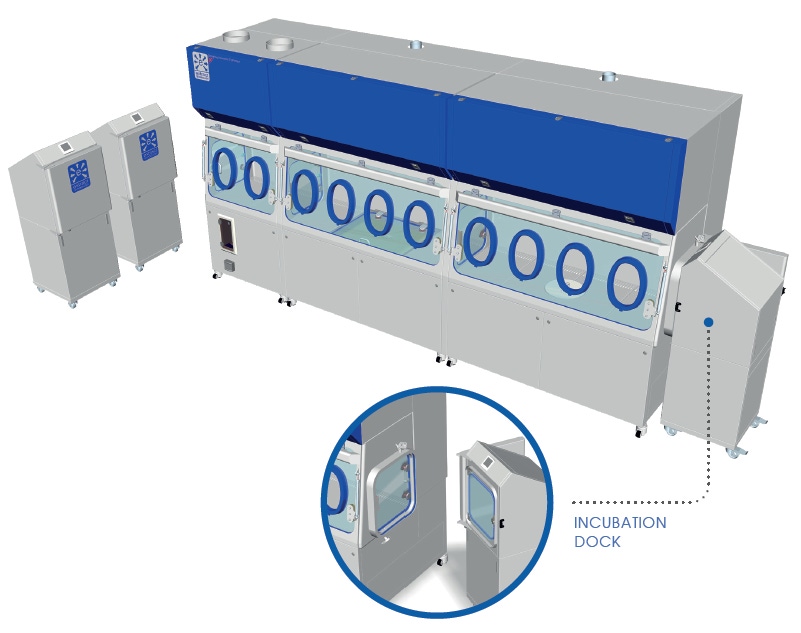

ATMP (Advanced Therapies Medicinal Products) requires more advanced process equipment and technologies. The Extract Technology Modular Cell Therapy Isolator (M-CTI) through experience within more traditional markets and by research and development meets the changing demands with its innovative flexible solution that enhances the production in a reliable, robust and cost-effective way.

The ultimate goal being the small part we can play in positively affecting patient lives.

You May Also Like