Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

February 20, 2017

Sponsored by Charter Medical

For years, availability has cornered cell therapy manufacturers into utilizing transfer sets intended for other industries and applications. These transfer sets or accessory sets are not designed for cell therapy, and therefore lack key requirements, essential to clinical and commercial manufacturing.

Many current personalized cell therapies are highly manual in practice, and require numerous ancillary components and handling steps. Modifications to these processes further complicate this inherently challenging process. These deviations impact the reproducibility of the manufacturing platform, as well as the quality of the final product. To mediate these risks, it is important to understand the factors that should be considered when selecting a transfer set.

For cell therapy applications, it is important to utilize quality materials. Depending on the ancillary material and the intended use within the manufacturing process, quality aspects including biocompatibility, extractables and leachables, particulates, or cell recovery/viability may be impacted. Early implementation of high quality materials, with the appropriate components, testing, and supporting validation will reduce risks. It is encouraged to use the highest quality products or devices within your process as they guarantee supporting documentation and use of qualified, safe materials.

Packaging is an equally important consideration when selecting transfer sets. Inadequate packaging results in the need for excess handling and cleaning steps. Selection of materials that are cleanroom ready can save time as well as reduce potential contaminants and particulates entering the production suite and final product.

Regulatory compliance requirements are an additional undertaking that is typically encountered in the later stages of clinical trials spanning different regions. The issue is that cGMP requirements cannot always be interchangeable between varying regulatory compliance requirements, and may result in unnecessary delays.

Transfer sets or accessory sets are an especially critical component for enabling personalized cell therapy production given their high usage frequency. Transfer sets should be selected with the correct components, performance, and quality assurance.

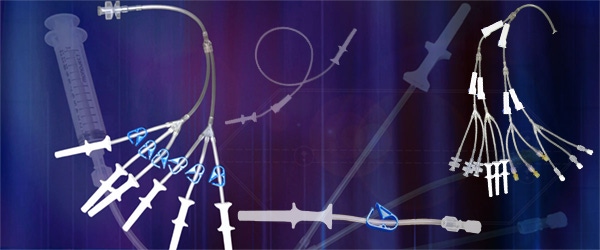

By incorporating transfer sets designed for cell therapy, this will allow the implementation of controllable, consistent, and safe cGMP manufacturing procedures. Until now, there have not been commercially available cell therapy transfer sets that are available in many configurations, manufactured without DEHP, and that are cleanroom compatible. Charter Medical recently released a new product line featuring sixteen configurations of Cell Therapy Fluid Transfer Sets. These medical devices are intended for sterile transfer of cell based products, including whole blood and cell suspensions, from one container to another. These transfer sets fill industry gaps, providing quality components that are fully tested and validated, not manufactured with DEHP, and feature double packaging, making them cleanroom ready. They are CE Marked, and currently available for sale in Europe. It is expected that they will be available in the United States in 2017 and additional regions following. Sign up on chartermedical.com for newsletters about US availability.

You May Also Like