Content Spotlight

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

December 10, 2015

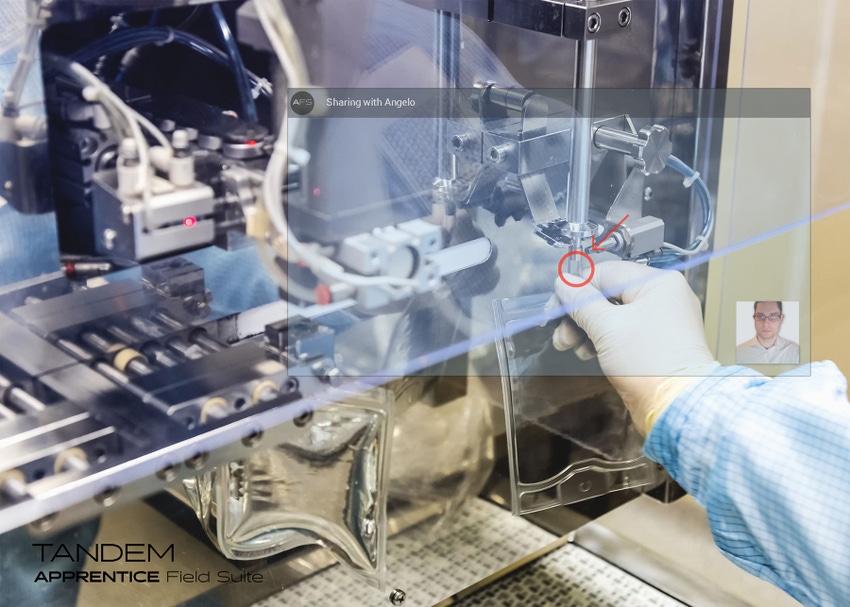

Apprentice Field Suite (AFS) announces it has expanded its portfolio of award-winning applications that allows engineers and operators to see and repair manufacturing issues in real time without physically being on-site – reducing downtime, improving accuracy, and increasing site and product safety. As with all AFS solutions, the newest application, Tracer, leverages augmented reality (AR), computer vision, and cutting-edge smart glasses to help operators and engineers make informed decisions – hands-free.

Tracer leverages Epson’s BT-2000 Smart Headset to create a unique solution for indoor location tracking. It can be used to create an employee efficiency analysis when walking throughout a facility. Tracer complements the other AFS applications, which were designed specifically to meet biopharma manufacturing needs.

“Biopharma manufacturing is extremely complex. It requires unshakeable supply chains and production, as companies can lose thousands of dollars each minute a line is down. Additionally, worker safety is an ever-present concern. Even inexperienced operators can use an effective hands-free tool to access data to make informed decisions. Our applications for smart glasses is the first solution that addresses all these market concerns,” said Angelo Stracquatanio, co-founder of AFS.

In addition to Tracer, AFS offers three other applications, all of which are 21 CFR Part 11 compliant and developed specifically for the biopharma market:

The Tandem app creates a collaborative telepresence, where a remote engineer can see the operator’s field of vision in real-time, and assist in troubleshooting without actually being on the plant floor. It greatly reduces the time spent troubleshooting and can save tens of thousands of dollars in downtime.

Manuals serves as a virtual instruction manual that provides hands-free access to the latest standard operating procedures, batch records, or job plans. Providing a fully animated step-by-step AR overlay or a simple list of text-based procedures, it eliminates costly errors due to incorrect or out-of-date procedures while increasing employee speed, efficiency, and accuracy.

Gauge is computer vision software that automatically alerts an operator when a bioreactor is in-use before millions of dollars and countless hours are lost due to accidentally working on the wrong vessel. It also reads and saves analog and digital gauge values. Optional photo/video capability allows self-reporting of unsafe conditions, eliminating the need for paper records and streamlining the notification chain.

The first three members of the AFS Smart Glasses suite are currently being used by a number of Fortune 100 Biopharma companies. These corporations have realized decreased troubleshooting time, as well as improved productivity, quality, reliability and safety.

All of the AFS applications are built on a propriatary Android library, for maximum platform flexibility. They interface with a scalable, cloud-based API to make managing employees, workflows, sessions, equipment and reporting easier.

You May Also Like