Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

August 15, 2014

Avid Bioservices is a contract manufacturing organization (CMO) specializing in mammalian cell culture process development and current good manufacturing practice (CGMP) production of clinical- and commercial-scale monoclonal antibodies, recombinant proteins, and enzymes. Committed to your success, our team is constantly striving to build partnerships that extend well beyond the delivery of product. By combining our knowledge and experience with a flexible and efficient approach, we can meet your specific project requirements.

Avid Bioservices is a contract manufacturing organization (CMO) specializing in mammalian cell culture process development and current good manufacturing practice (CGMP) production of clinical- and commercial-scale monoclonal antibodies, recombinant proteins, and enzymes. Committed to your success, our team is constantly striving to build partnerships that extend well beyond the delivery of product. By combining our knowledge and experience with a flexible and efficient approach, we can meet your specific project requirements.

Established CMO with Proven Capabilities

nearly two decades of proven experience in custom and commercial-scale biomanufacturing

manufacturer of commercial biologic products since 2005

robust global regulatory inspection history by US FDA, ANVISA, and European authorities

experienced management team focused on process development, regulatory approvals, and product commercialization

individualized and dedicated project management supporting every phase of production from clone to commercial

comprehensive analytical capabilities to support lot release and stability studies.

Excellence in Process Science

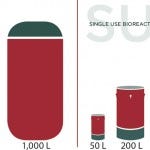

FIGURE 1: Bioreactor capacity

Avid’s process sciences group is focused on the development of process and analytical methods needed to deliver active products for transfer to CGMP manufacturing. Our experience with CHO-based IgG production, as well as knowledge in the areas of recombinant protein and enzyme process development, provide the expertise you need to advance your programs to the next phase. Expertise includes

developed multiple CHO cell lines producing monoclonal antibodies for clinical development

optimized CHO cell culture parameters for a Phase II clinical project resulting in 5 increase in yield at the 1,000-L scale, with comparable product quality

identified critical process parameters through quality by design (QbD) studies to create a robust process with high product quality and consistent critical product quality attributes (CQAs)

conducted comparability studies to seamlessly transition from early-stage, low-yield processes to fully disposable, high-yield commercial processes that meet regulatory approval.

Experience to Bring Your Product to Market

Avid’s established CGMP facility provides 8,000 ft2 of manufacturing space dedicated to mammalian cell culture and is able to produce clinical and commercial biologics. Bioreactors ranging from 50 to 1,000 L in both stainless steel and single-use configurations offer scalable and flexible solutions to meet a variety of capacity demands (Figure 1). Experience includes

production of monoclonal antibodies and recombinant proteins used in clinical trials since 1997

experienced working with various cell lines, including CHO, NS0, NS1, and hybridoma

>25 different monoclonal antibodies and recombinant proteins produced for clinical and commercial use

proven track record in bringing products from early development to market.

Kelly Pisarev Lord is manager of marketing communication at Avid Bioservices,14282 Franklin Avenue, Tustin, CA, 1-714-508-6100;

[email protected]; www.avidbio.com

You May Also Like