Voices of Biotech

Podcast: MilliporeSigma says education vital to creating unbreakable chain for sustainability

MilliporeSigma discusses the importance of people, education, and the benefits of embracing discomfort to bolster sustainability efforts.

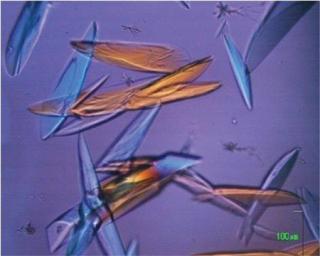

Two decades of intensive development of novel expression systems for mammalian cells and microorganisms have led to a significant increase in fermentation titers in the biopharmaceutical production of proteins (more than 20 g/L in microbials and more than 4 g/L in mammalian cell culture). However, dynamic binding capacity of chromatography resins is often limited, and very large chromatography columns are needed to purify such large amounts of target proteins. New paths for cost-efficient purification are therefore needed, including downstream processing steps that can cope with high fermentation titers and that can fulfill the increasing market demand for biopharmaceutical proteins. Preparative crystallization of biopharmaceutical proteins has the potential to dissolve bottlenecks in large-scale downstream processes and may be an alternative to costly unit operations such as liquid chromatography.

Because there is a general lack of knowledge about multikilogram cystallisation processes, substantial efforts have been made at Boehringer ingelheim’s process science department to overcome those limitations. a very efficient systematic development approach has therefore been set up for bulk crystallization processes that have been practically approved with a wide variety of proteins. Successful Scale-Up

To date, using this systematically and practically approved approach, a wide variety of biopharmaceutical proteins — such as single-chain antibody fragments, growth factors, and interferons — were successfully crystallised from downstream intermediates, in particular from crude homogenate, resulting in high product purity. Yields in the range of 95%, with the highest quality and process robustness, can be achieved even from crude cell lysates. at our production facility in Vienna, Austria, we have successfully upscaled this process to several kilograms per batch. this development enables the implementation of downstream processes whereby several time-consuming and expensive chromatographic steps can be replaced by the use of crystallization.

Crystallization of Monoclonal Antibodies

At our mammalian cell culture facility in Biberach, Germany, the department of downstream development works on the challenge of crystallizing antibodies, which are composed of large, complex molecules. Although crystallization of full-length monoclonal antibodies (MAbs) has been a subject of significant interest for the past three decades, very few intact MAbs have ever been crystallized. Boehringer Ingelheim was able to crystallize an IgG antibody with a yield of 98% under optimized conditions, resulting in no measurable loss of binding activity in the redissolved antibody. Crystallization is therefore an innovative path to purify biopharmaceuticals during downstream processes in a fast and economically valuable way. In addition, protein crystallization has the potential to become a new economical tool for the stable formulation and storage of biopharmaceuticals. Crystallization of macromolecule pharmaceuticals can offer significant advantages, including high stability, controlled release of activity, and high doses at the delivery site, which are attractive for MAb therapies.

About the Author

Author Details

Dr. Matthias Berkemeyer is head of downstream development, Process Science Austria, and Dr. Franz Nothelfer is associate director of purification development at Boehringer Ingelheim Pharma GmbH & Co KG, 49-6132-770; [email protected]www.biopharma-cmo.com.

You May Also Like