- Sponsored Content

- Cell Therapies

- Gene Therapies

- Contract Services

Setting the Standard in Cell- and Gene-Therapy Manufacturing: Tackling Performance, Scalability, and Regulatory Compliance Challenges Together

Sponsored by Sartorius

In 2023, the biopharmaceutical industry marked a record year with 71 new drug approvals (1). Seven of those were cell and gene therapies (CGTs), including the first CRISPR/Cas9-edited therapies, bringing the total of CGTs approved by the US Food and Drug Administration (FDA) to 34. The thousands of other CGT candidates in preclinical development highlight the rapid growth and promising future of these modalities.

Clinical success across a growing list of conditions has placed significant demands on CGT developers to speed therapies to the market. The high cost per dose has added pressure to reduce cost of goods and increase patient access, necessitating high-yielding, productive, and efficient production processes. A 2023 survey also reports that although 90% of respondents held a positive outlook for the CGT industry over the next 12–18 months, nearly 40% lacked confidence in their current manufacturing capabilities (2).

CGT clinical trials account for <2% of all trials listed with US regulators but represent around 40% of all clinical holds. Over a quarter of CGT holds are due to concerns with chemistry, manufacturing, and controls (CMC) and preclinical issues (3). Clearly, successful CGT development involves many factors, not least concerns about performance, scalability, and regulatory compliance.

Sartorius is dedicated to advancing the CGT space toward maturity. Over a decade of organic growth, significant facility expansions, and strategic acquisitions (see the “Key Acquisitions” box), we have established a comprehensive suite of tailored solutions spanning from discovery to commercial manufacturing. Close collaboration with customers has given us invaluable insights into industry successes and obstacles. Our offerings play a crucial role in the production of numerous CGTs, both approved and in development. Together, we are setting the standard in CGT manufacturing.

Focusing on gene therapy, this article shares insights into challenges that you might encounter in your CGT process and discusses solutions that can help you achieve breakthroughs.

Challenge 1: Performance

A robust process is essential for ensuring performance, which helps prevent batch failures and associated costs. But CGT products are complex and sensitive, and their production processes are highly variable compared with those for classical biologics such as monoclonal antibodies (mAbs).

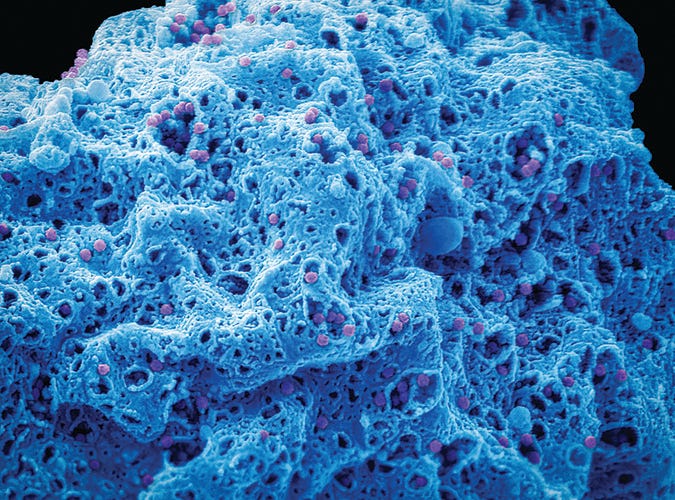

In gene therapy, variability can occur at many levels. At the product and process level, different viral vectors and strains require distinct process development (PD) and optimization strategies. The same is true for culture methods (adherent and suspension), host cells (mammalian and insect), and gene-delivery techniques (transient transfection and coinfection). For example, empty:full capsid ratios vary across adenoassociated virus (AAV) serotypes, and release of AAVs by cell lysis or secretion can affect attributes such as feed impurity and turbidity.

At the batch level, differences in raw materials, media, and cells can cause variation in bioreactor titers, impurity profiles, and product homogeneity. For instance, viral particles produced by host cells can show heterogeneity in capsid compositions, posttranslational modifications, and empty:full:partially full capsid ratios. Such variabilities can lead to unpredictable yields and out-of-specification product quality.

Compounded by the nascency of the CGT field is a lack of deep process understanding and production platforms. Process performance often suffers as a result, impacting time to market. Applying an appropriate PD strategy to generate data for deep process knowledge is critical.

Ensuring reproducible viral-vector production requires a high-performing, automated, scalable process; optimized media and transfection reagents for high viral titers; and a standardized purification platform that provides high yields for multiple serotypes.

Implementing Sartorius’s high-throughput, automated technologies provides a robust foundation for your gene-therapy manufacturing platform. Those include systems for screening raw materials and tangential-flow filtration (TFF) filters that enhance PD efficiency as well as intuitive data-analytics platforms that enable fast decision-making. Our technology platforms are fully scalable and modality-specific. They include an array of optimized raw materials to improve viral titers. High-capacity filtration and chromatography products are suitable for multiple AAV serotypes, and we use low-shear technologies to address the sensitivity of lentiviral vectors (LVVs).

Challenge 2: Scalability

CGT manufacturers face the challenge of substantially increasing production scale when transitioning processes from PD to manufacturing or when adjusting processes to meet increased patient demand. If cost-effective, scalable technologies have not been selected during PD, then processes could exhibit limited productivity. Subsequent revalidation and optimization requirements can incur significant costs and delays if modifications are made after approval.

Technologies applied early in PD for ease of use or fast implementation can be difficult to transition to large scales. For example, adherent-cell culture is difficult to sustain at large volumes: Obtaining a clinically relevant number of cells per dose involves high consumption of expensive raw materials. Host cells can behave unpredictably during transitions from small- to large-volume bioreactors. Most gene-therapy production processes involve transfection, which is difficult to scale up and requires optimized plasmids and transfection-agent complexation for high efficiency. Increased media volume requirements can strain your existing supply chain.

LVVs are particularly challenging for filtration because of their large size (~120 nm). Sterile-filtration and clarification steps often result in high product loss and low filter capacity, respectively. Thus, scale-up can require filtration consumables much larger than those used for mAbs and even AAVs. In addition, a small stability window and shear sensitivity make LVVs difficult to purify. Such factors are crucial to consider when systems are scaled up and as handling times increase.

Thus, successful scale-up hinges on a robust, scalable expansion platform that supports suspension cultures for viral vectors, along with reliable access to media and raw materials required for seamless process transfer to larger volumes. Geometrically consistent bioreactor vessels and scalable downstream technologies improve process consistency during scale-up.

Our portfolio of bioreactors, single-use bags, cell-culture media, plasmids, and transfection reagents is designed to simplify upstream scale-up. During large-volume downstream processing, our filtration and purification offerings maintain high product yield and quality to improve cost efficiency. We also offer preassembled solutions to protect CGTs during storage and shipping.

Challenge 3: Compliance

The complex and evolving regulatory landscape for CGTs can include significant barriers to commercialization. Adhering to the latest requirements is critical to simplifying interactions with health authorities and ensuring swift approvals. A major difficulty is that CGTs are subjected to the same general requirements used for other biopharmaceuticals. However, methods established for classical biologics often are unsuitable for CGTs. One example is viral safety. It is usually impossible to perform standard viral inactivation or filtration on a CGT without compromising it. Novel tools and mitigation approaches are needed.

Maintaining a robust manufacturing process requires automation and closed systems; good manufacturing practice (GMP)–compliant technologies, consumables, and raw materials; and relevant regulatory support.

Sartorius products and services are backed by rigorous quality-assurance processes and certified documentation that is trusted worldwide. We offer sterile single-use systems for closed, aseptic processing; serum- and xeno-free cell-culture media and reagents to protect against contamination; biosafety testing and validation services; and expert regulatory support to help you meet efficacy and safety standards.

Facilitating CGT Approvals

A smooth journey toward CGT commercialization requires a trusted partner with expertise, experience, and end-to-end GMP solutions that provide the performance, scalability, and quality needed to simplify approvals. From drug discovery to commercial manufacturing, our proven solutions can help you accelerate time to market while reducing costs. Together, we are setting the standard in CGT.

References

1 Senior M. Fresh from the Biotech Pipeline: Record-Breaking FDA Approvals. Nature Biotechnol. 26 February 2024; https://doi.org/10.1038/s41587-024-02166-7.

2 Mooraj H, et al. Mooraj H, et al. 2023 Cell and Gene Therapy Industry Survey: Reflections on and Vision for the Cell and Gene Therapy Industry. Deloitte Consulting: New York, NY, 2023; https://www2.deloitte.com/us/en/pages/life-sciences-and-health-care/articles/cell-gene-therapy-market-insights-survey.html.

3 Wills CA, Drago D, Pietrusko RG. Clinical Holds for Cell and Gene Therapy Trials: Risks, Impact, and Lessons Learned. Molec. Ther. Meth. Clin. Dev. 31, 2023: 101125; https://doi.org/10.1016/j.omtm.2023.101125.

Prity Bengani-Lutz is senior marketing business partner for separations, Lorraine Borland is senior marketing expert for bioprocess solutions ([email protected]), Paul Cashen is a process technology consultant, David Ede is process technology manager for gene therapies, Katy McLaughlin is a scientific content writer, and Marc Noverraz is a process technology consultant for viral-based therapeutics, all at Sartorius.

You May Also Like